Kverneland 7710

Wrapper | Turn Table Wrapper

Kverneland 7710 is ideal for ’wrap and stack’ operations

Three-point mounted turntable wrapper

The advantages of this Turn Table Wrapper

- Three-point mounted turntable wrapper

- Ideal solution for wrapping at the storage site.

- Able to handle round bales up to 1200 kg

- DuoWrap twin pre-stretcher for faster wrapping

- Hydraulic film cutter

Description

Kverneland 7710 series are three-point mounted wrappers, ideal for ’wrap and stack’ operations when the bale is being transported to the storage site for wrapping. It can be mounted on the rear or front hydraulics of the tractor or used as a static machine with an external power pack. Kverneland 7710 models can be specified with a single pre-stretcher or HSP twin film pre-stretcher feature.

Features

Features

- Stable wrapping and gentle discharge.

- Reduces damage risk.

- Smooth handling.

- Turntable with two driven rollers designed for high bale stability and smooth, even rotation

- DuoWrap twin film pre-stretcher for faster wrapping.

- Consistent film stretch reduces tear risk.

- One-hand roll loading system

- Hydraulically operated for precise cutting and holding.

- Cuts and holds film efficiently for the next cycle

- Computer Control (C): Fully or semi-automatic operation.

- An advanced remote-controlled version is available on C versions of turntable wrappers. Place the bale on the wrapper, press one key on the remote control, and the wrapping process starts.

- Bale Turner guarantees that bales are discharged on their ends, offering improved protection against damage.

- The High-Speed Pack (HSP) guarantee optimum and high wrapping speed, thanks to the Optispeed sensor and the DuoWrap double pre-stretch

The DuoWrap sees twin film dispensers integrated into the Kverneland 7710, 7730 and 7740 mounted and trailed turntable wrappers. DuoWrap gives up to 50% faster wrapping compared to single film models, whilst also reducing the risk of film breaking during wrapping. Utilising a 66% overlap of the two films as they are applied to the bale, DuoWrap ensures even coverage without excessive wrinkling of the film.

The HSP is a combination of two developments. The first, DuoWrap allows wrapping with two film overlap of 66% , the time to cover the bale is reduced by one third. The second development, named OptiSpeed, is electronic control of the wrapper table rotation speed.

The OptiSpeed optimizes the rotation speed of the table to allow the fastest wrapping possible in all conditions without being limited to fixed values.

HSP option is available on the 7710C fully mounted model and 7740C heavy duty trailed models.

- Two large diameter rollers, both of which are driven, ensure bale rotation even in the most difficult conditions.

- Four endless belts carry and rotate the bale evenly during wrapping with no risk of film damage.

- The two large diameter conical side support rollers ensure that the bale is kept in a central position on the rotating table during wrapping operation.

Computer Control (C)

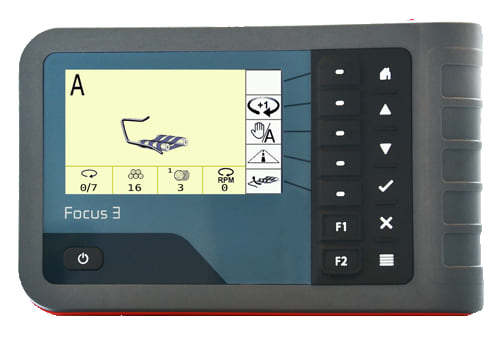

- The computer (Focus 3) controlled C models turn the wrapper into a fully automatic machine offering either a fully automatic operation or a choice of manual override or function by function operation.

- Choose for example that you want the bale to wrap automatically off. One operator does the entire process of loading, wrapping and stacking when loaded, but remain on the wrapping table until you confirm that you want to offload.

- Compact joystick allows temporary manual control of the bale loading and turntable rotation/tip.

Remote Control (R)

- An advanced remote controlled version is available as an option on C versions of turntable wrappers. Place the bale on the wrapper, press one key on the remote control, and the wrapping process starts.

- The previously wrapped bale is stacked and the next one picked up while the machine continues wrapping.

- Press another key when wrapping is completed and the bale is tipped off. One operator does the entire process of loading, wrapping and stacking.

Mechanical Cable Control (M)

- The manual versions (M) are controlled with manual cable control with levers.

- A wrap and bale counter is fitted for easier control of film layers, as well as number of bales wrapped.

- An automatic table stop that is controlled by the wrap-and-bale counter is fitted as standard.

- This converts the wrapper from manual to semi-automatic, as it allows the wrapping function to stop automatically at the set number of table revolutions.

- On the Kverneland 7710, 7730 and 7740 a hydraulically operated film cutter cuts and holds the film in position ready to wrap the next bale.

- An easy to use solution without the need to manually control the operation.

- On the Kverneland 7710, 7730 and 7740 a hydraulically operated film cutter cuts and holds the film in position ready to wrap the next bale.

- An easy to use solution without the need to manually control the operation.

- Two large diameter rollers, both of which are driven, ensure bale rotation even in the most difficult conditions.

- Four endless belts carry and rotate the bale evenly during wrapping with no risk of film damage.

- The two large diameter conical side support rollers ensure that the bale is kept in a central position on the rotating table during wrapping operation.

The DuoWrap sees twin film dispensers integrated into the Kverneland 7710, 7730 and 7740 mounted and trailed turntable wrappers. DuoWrap gives up to 50% faster wrapping compared to single film models, whilst also reducing the risk of film breaking during wrapping. Utilising a 66% overlap of the two films as they are applied to the bale, DuoWrap ensures even coverage without excessive wrinkling of the film.

Computer Control (C)

- The computer (Focus 3) controlled C models turn the wrapper into a fully automatic machine offering either a fully automatic operation or a choice of manual override or function by function operation.

- Choose for example that you want the bale to wrap automatically off. One operator does the entire process of loading, wrapping and stacking when loaded, but remain on the wrapping table until you confirm that you want to offload.

- Compact joystick allows temporary manual control of the bale loading and turntable rotation/tip.

Remote Control (R)

- An advanced remote controlled version is available as an option on C versions of turntable wrappers. Place the bale on the wrapper, press one key on the remote control, and the wrapping process starts.

- The previously wrapped bale is stacked and the next one picked up while the machine continues wrapping.

- Press another key when wrapping is completed and the bale is tipped off. One operator does the entire process of loading, wrapping and stacking.

Mechanical Cable Control (M)

- The manual versions (M) are controlled with manual cable control with levers.

- A wrap and bale counter is fitted for easier control of film layers, as well as number of bales wrapped.

- An automatic table stop that is controlled by the wrap-and-bale counter is fitted as standard.

- This converts the wrapper from manual to semi-automatic, as it allows the wrapping function to stop automatically at the set number of table revolutions.

The HSP is a combination of two developments. The first, DuoWrap allows wrapping with two film overlap of 66% , the time to cover the bale is reduced by one third. The second development, named OptiSpeed, is electronic control of the wrapper table rotation speed.

The OptiSpeed optimizes the rotation speed of the table to allow the fastest wrapping possible in all conditions without being limited to fixed values.

HSP option is available on the 7710C fully mounted model and 7740C heavy duty trailed models.

Technical specifications

Technical specifications

Download brochure| 7710 C | ||

|---|---|---|

| Max bale size (m): | 1.20 x 1.50 | |

| Max bale weight (kg): | 1200 | |

| Control function: | Computer control |

Technical specifications

Technical specifications

Download brochureMax Bale Size |

Max Bale Weight |

Control System |

|

7710 C |

1.20x1.50m |

1200kg |

Computer Control (C) |