f-drill compact / maxi

Seeder | Pneumatic Mounted Seed Drill

With flexibility ready for the future

The front mounted hopper, Kverneland f-drill, ensures even weight distribution across the machine arrangement providing the maximum balance. The front-mounted position of the hopper, improves both safety, manoeuvrability and gives an unrestricted view over the machine set-up.

The advantages of this Pneumatic Mounted Seed Drill

- Utmost flexibility – for all kind of farming systems

- Safe manoeuvrability due to even weight distribution

- Reduced soil compaction

- Long lifetime of the corrosion resistant plastic hopper

- Precise and intelligent seed application

- Reduced set-up time due to large hopper capacity

Description

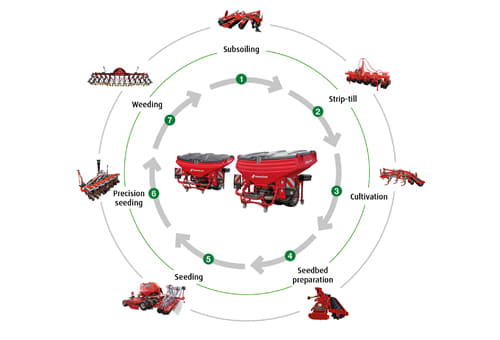

The f-drill has been designed to give farmers and contractors utmost flexibility as it adapts to all kind of farming systems. The f-drill model range is ready for combination with different implements like a seeder or cultivator and for operation in various working widths.

Seeding and fertilising, seeding and cultivation or fertilising and cultivation as strip-tillage in one pass is possible as well as the combined application of seeds and companion crops. Due to the clear design and the high level of incorporated intelligent technology, the f-drill offers maximum ease of use, from set-up and filling, to balanced transport with good overview in front and rear of the tractor.

Sustainable farming practices for healthy soil and high yields

Soil - your most valuable asset

Healthy soil structure is the foundation of sustainable agriculture. A well-prepared and even seedbed ensures consistent crop emergence and optimum plant development. To protect soil quality, farmers should focus on reduced passes, proper weight balance, and the right timing to prevent soil compaction and wheeling damage.

Supporting biodiversity with multi-cropping

Practices such as multi-cropping and companion cropping play a vital role in promoting biodiversity and protecting soil from erosion. By combining different crops in the same field, farmers can suppress weeds, stabilize soil, and improve overall ecosystem health.

Precision fertilisation for sustainable growth

A precise fertiliser application at the right time is essential for crop health and long-term sustainability in farming. Efficient nutrient use supports healthy rooting, reduces leaching, and increases humus content and CO₂ storage capacity, strengthening both soil fertility and climate resilience.

Innovative equipment for efficiency and longevity

Modern farming equipment such as the Kverneland f-drill supports sustainability by allowing several tasks to be combined in one pass, saving both time and fuel while protecting the soil. Its lightweight hopper design, made from durable, corrosion-resistant plastic, ensures high capacity, long service life, and optimal weight distribution for minimal soil impact.

Features

Features

Precise seed metering, automatic and safe

- ELDOS is the electric driven metering device for Kverneland pneumatic seed drills.

- ELDOS is steered by Kverneland e-com software, which is fully ISOBUS compatible.

- By the automatic section control, GEOCONTROL, the metering device stopps/starts automatically. Double and/or missed seeding on headlands or odd-shaped fields is avoided. Special sensors ensure complete functionality from the tractor cab.

- Calibration is automatic, and a range of interchangeable seed metering rotors can be swapped - even when the hopper is full - without the need for tools. Sensors monitor the metering rotors, and give a warning if the wrong metering rotors are accidentally installed.

- The f-drill is available with one or two ELDOS metering units. Two ELDOS are possible if larger quantities have to be applied as with the duo models.

- If the hopper is divided as plus version, there are also two ELDOS available to have the possibility to apply either two different seeds or seeds and fertiliser in one pass.

- The entire system is based on the Venturi principle. No additional effort is required to keep the system tight. The Venturi system guarantees the accuracy of the desired dosage and also the adherence to higher application rates.

For all kind of combinations and applications in various working widths

- A wide range of fine to larger seeds and fertiliser can be applied.

- It allows seeding and fertilising in one pass

- It allows the combined application of seeds and companion crops

- In spring the Kverneland f-drill can be used as a fertiliser hopper with the Optima F or with the Kultistrip for strip tillage. When joined with a power harrow drill combination such as the Kverneland e-drill, the f-drill can be used as an additional seed hopper for sowing companion or spring crops.

- In summer and autumn, the hopper can be combined with the power harrow range and coulter bars to have a compact combination from 3.0 up to 6.0m working width.

Modern design for low maintenance and long lifetime

- The f-drill made of plastic has a modern design which ensures low maintenance and long lifetime also when working with corrosive material such as fertiliser.

- The f-drill front hoppers are available in two sizes and three versions.

- The f-drill compact has a capacity of 1600 litres and the f-drill maxi up to 2200 litres.

- The standard version is equipped with one ELDOS metering unit. Either seeds or fertiliser can be filled into the hopper.

- Higher application rates can be achieved by the duo version, as two ELDOS units distribute two times up to 400kg/ha of one type of fertiliser or seeds.

- The hopper of the plus model is divided into two sections. This allows either two types of seeds or one type of seeds and fertiliser to be applied in one pass. The ratio of the hopper split is 60:40.

Easy filling and lifting

- The large hopper capacity of up to 2,200 litres reduces the set-up time.

- The hopper covers open sidewise and lock automatically supported by gas cylinder.

- The hopper made from plastic can easily be filled using e.g. big bags, a front loader or a telescopic handler.

- The parking wheels are available for quick and easy storage. The f-drill can easily be hitched. There is no PTO shaft needed.

- Pipes installed on the side of the cab convey the seed or fertiliser to the coulters by an air stream.

Increased safety and manoeuvrability

- The dissolved structure of the Kverneland f-drill ensures an even weight distribution across the machine arrangement, giving the tractor the best balance at maximum capacity.

- This improves both safety and manoeuvrability whilst at the same time giving the driver an unrestricted view over the entire machine set-up.

- The wheel packer with lifting function relieves the load on the front axle while maintaining good steering ability.

- The packer is self-steering and pull-attached which reduce power requirement and fuel consumption. In addition it also avoids the bulldozing effect.

- Especially in wet periods, the dissolved design with its better weight distribution reduces the impact on the soil structure

Technical specifications

Technical specifications

Download brochure| Model | Kverneland f-drill compact | Kverneland f-drill maxi | Kverneland f-drill compact duo | Kverneland f-drill maxi duo | Kverneland f-drill compact plus | Kverneland f-drill maxi plus | |

|---|---|---|---|---|---|---|---|

| Machine type | modular mounted | modular mounted | modular mounted | modular mounted | modular mounted | modular mounted | |

| Hopper capacity (l) | 1,600 | 2,200 | 1,600 | 2,200 | 1,600 (60:40) | 2,200 (60:40) | |

| Machine width (m) | 2.75 | 2.75 | 2.75 | 2.75 | 2.75 | 2.75 | |

| Weight base machine (kg) | 658 | 678 | 732 | 752 | 747 | 767 | |

| Weight optional front packer (kg) | 361 | 361 | 361 | 361 | 361 | 361 | |

| Ballasting weights 100 - 600kg (steps 2 x 50kg) | Option | Option | Option | Option | Option | Option | |

| Min. power requirement (HP/Kw) | 106/80 | 173/130 | 106/80 | 173/130 | 106/80 | 173/130 | |

| Hydraulic fan drive closed centre | Standard | Standard | Standard | Standard | Standard | Standard | |

| Hydraulic fan drive open centre wih adjustment valve | Option | Option | Option | Option | Option | Option | |

| Hydraulic fan drive power beyond load sensing | Option | Option | Option | Option | Option | Option | |

| Oil charge hydr. fan (l/min) | 30 | 30 | 40 | 40 | 44 | 44 | |

| ELDOS electric driven metering device (no.) | 1 | 1 | 2 | 2 | 2 | 2 | |

| Metering units in relation to the no. of distribution heads | 1 | 1 | 2 | 2 | 2 | 2 | |

| e-com electronic (Tellus) | Standard | Standard | Standard | Standard | Standard | Standard | |

| Working switch for metering unit (start/stop) on top link for older tractors | Option | Option | Option | Option | Option | Option | |

| Metering device control | Standard | Standard | Standard | Standard | Standard | Standard | |

| Seed rate adjustment | Standard | Standard | Standard | Standard | Standard | Standard | |

| Seed quantity (min-max.) - kg/ha* | 1-400 | 1-400 | 2-600 | 2-600 | 2 x 1-400 | 2 x 1-400 | |

| Ø 100mm distribution system | Standard | Standard | Standard | Standard | Standard | Standard | |

| Ø 135mm distribution system | Option | Option | Option | Option | Option | Option | |

| Radar speed signal | Standard | Standard | Standard | Standard | Standard | Standard | |

| Calibration set | Standard | Standard | Standard | Standard | Standard | Standard | |

| Quick empyting chute | Standard | Standard | Standard | Standard | Standard | Standard | |

| Low level sensor | Standard (1) | Standard (1) | Standard (2) | Standard (2) | Standard (2) | Standard (2) | |

| Weight cell system | Option | Option | Option | Option | Option | Option | |

| Platform | Standard | Standard | Standard | Standard | Standard | Standard | |

| Lighting equipment | Standard | Standard | Standard | Standard | Standard | Standard | |

| Working lights | Option | Option | Option | Option | Option | Option | |

| Camera system | Option | Option | Option | Option | Option | Option | |

| Working width seed coulter bar (m) | rigid and fold versions (3 - 6 m) with CX-II coulter | rigid and fold versions (3 - 6 m) with CX-II coulter | fold: 5.0m; 6.0m with CX-II coulter | fold: 5.0m; 6.0m with CX-II coulter | rigid and fold versions (3 - 6 m) with CX-II double entry coulter | rigid and fold versions (3 - 6 m) with CX-II double entry coulter | |

| No. of precision planter rows | 4-8 | 4-8 | 12-16 | 12-16 | 12-16** | 12-16** | |

| Hydr. spool valves 1 sa + pressless return for fan drive | Standard | Standard | Standard | Standard | Standard | Standard | |

| Hydr. spool valves 1 sa + pressless return for fan drive and optional comfort front packer | Option | Option | Option | Option | Option | Option | |

| Additional hydr. spool valves 1 da for optional basic front packer lifting | Option | Option | Option | Option | Option | Option |

* with 15km/h working speed

** only if the dividing hopper plate is removed

Technical specifications

Technical specifications

Download brochureModel |

f-drill compact* |

f-drill maxi* |

f-drill compact duo** |

f-drill maxi duo** |

f-drill maxi plus*** |

Machine type |

modular mounted |

modular mounted |

modular mounted |

modular mounted |

modular mounted |

Hopper capacity (l) |

1,600 |

2,200 |

1,600 |

2,200 |

2,200 (60x40) |

Machine width (m) |

2.75 |

2.75 |

2.75 |

2.75 |

2.75 |

No. of ELDOS metering device |

1 |

1 |

2 |

2 |

2 |

Weight base machine (kg) |

658 |

678 |

732 |

752 |

767 |

Weight optional front packer (kg) |

361 |

361 |

361 |

361 |

361 |

Ballasting weights 100 - 600 kg (steps 2 x 50kg) |

Option |

Option |

Option |

Option |

Option |

Min. power requirement (HP/Kw) |

106/80 |

173/130 |

106/80 |

173/130 |

173/130 |

* Standard model: for the application of one type of seeds or fertiliser.

** The duo model: for higher application rates of one type of seeds or fertiliser.

*** The plus model: for two types of material.

* with 15km/h working speed

** only if the dividing hopper plate is removed