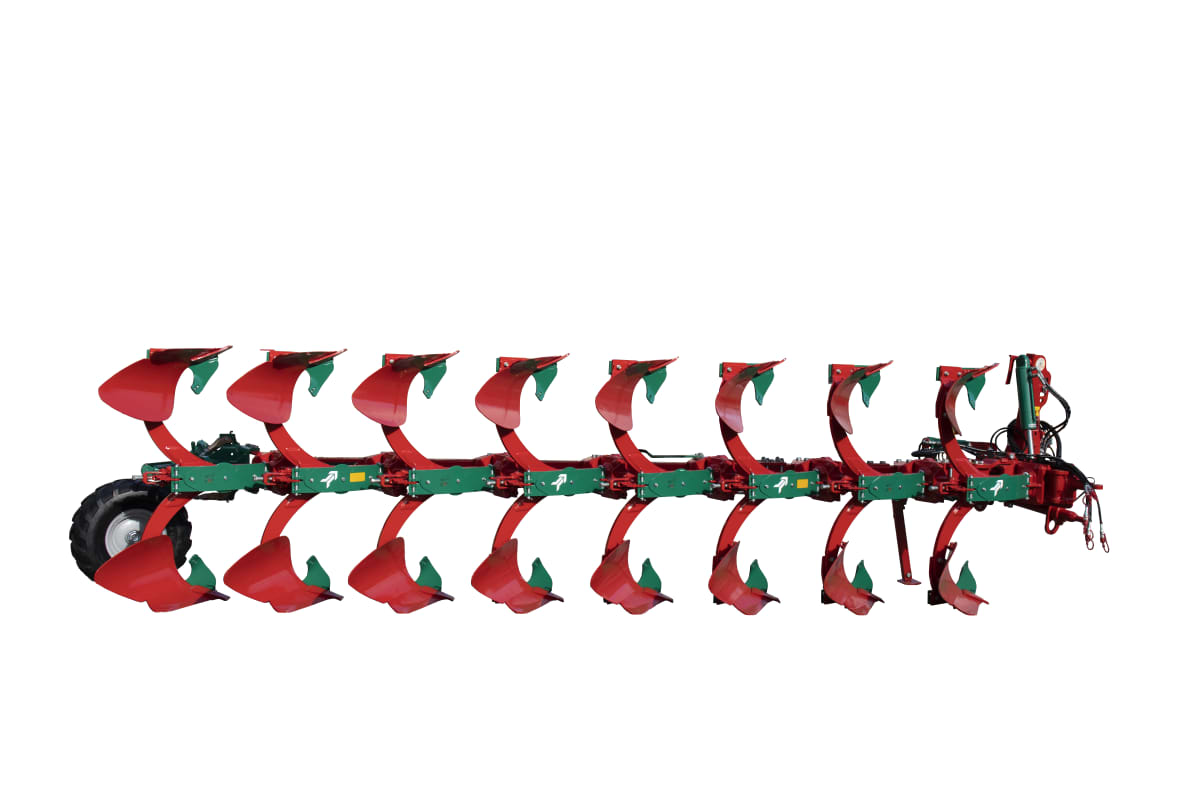

Kverneland ECOMAT

Plough | Eco Plough

Perfect for shallow ploughing

Research shows evidence that in some particular soil conditions, shallow ploughing is recommended. Kverneland Ecomat is then the answer: 5-8 furrows

The advantages of this Eco Plough

- Economical and time saving

- Improved soil structure

- Reduced problems with weeds, fungi and diseases

- Minimized chemical usage

- Better plant growth

Description

Compared to conventional tillage, the farmer saves time and energy. The result: an equally good crop with less effort. In comparison with reduced tillage system, the farmer benefits from a more secure and stable cultivation method for better results. The problem of weeds, fungus and other diseases also decreases. The farmer becomes less dependent on the weather and can work if the soil is relatively moist. Seeds will germinate and grow better in a clean, fine soil layer. Kverneland Ecomat Variomat® is a lightweight Auto-reset implement that tills the soil extremely efficiently via shallow ploughing (10-18cm). Kverneland steel or plastic bodies performance are unrivalled.

Features

Features

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

Unbeatable in stony conditions !

Kvernelands fully automatic non-stop Auto-Reset System is unbeatable when it comes to trouble-free ploughing in stony conditions. The clever multi-leaf spring system allows the plough legs to release over stones and other solid objects in a smooth and efficient manner. This avoids sudden jolts and possible damage. Once the obstruction is passed, the plough body automatically returns to the correct ploughing depth.

Safety compliance

With today's demands for higher output, both tractor and plough are expected to perform quicker than ever. This makes more arduous demands on the equipment, particularly on the safety systems designed to protect tractors, ploughs and drivers against the dangers encountered whenever the plough meets hidden obstructions in the ground. The Kverneland Auto-Reset system guaranties this safety high standars requirements.

Adaptable to varying soil conditions

Depending of the type of soil all Kverneland ploughs can be equipped with different leaf springs packages. For soft soils, a normal spring with 5 leaves is the best choice to obtain the perfect ploughing in stony conditions. Today, most Kverneland ploughs are delivered with the Heavy Duty springs package (HD) with 7 leaves. This will perform well in most conditions. If the soil is very hard and stony - a double leaf spring package is recommended.

Extra leaves when needed

The standard Auto-Reset system includes 7 Kverneland heat treated springs (640Kp).

For heavier to extreme soil conditions, extra leaf springs are added for up to 1400kp.

The leaves are easily fixed with one central bolt only.

Individual body release !

The Kverneland mechanical Auto-Reset system enables very plough body to release independently. A quality ploughing is therefore guaranteed.

Minimum wear and high second hand value

Kverneland's Auto-Reset System is a quite simple construction that withstands the punishing forces year in, year out, with a minimum of maintenance. Save time and money !

Moreover, the Kverneland auto-reset system guarantees a longer life to the plough. When hitting an obstacle, the pressure on the point, frame, plough parts, decreases. The stress on Kverneland ploughs is therefore reduced. Consequently, second hand Kverneland ploughs sell at a higher value than competitors ploughs.

*by using an Hydraulic system, pressure would increase

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Stepless Vari-width® system for infinite adjustments of working width. Kverneland’s world patented system is available either with hydraulic or mechanical furrow adjustments.

Benefits:

- Easy variation of ploughing capacity

- Perfect match at all time between tractor capacity, implement and soil conditions

- Time saving: up to 30% more capacity

- Cost saving: up to 18% reduction in fuel consumption in relation with increased ploughing capacity

- Better work: plough up to the hedges, fences, trees and ditches

- Minimum wear: unique non-wearing linkage joint between the beams and the mainframe section

- Perfect line of pull at all time. Kverneland’s Vari-width offers the correct parallel linkage along the whole plough. Therefore, lower draft requirement, minimum wear and tear.

Unbeatable in stony conditions !

Kvernelands fully automatic non-stop Auto-Reset System is unbeatable when it comes to trouble-free ploughing in stony conditions. The clever multi-leaf spring system allows the plough legs to release over stones and other solid objects in a smooth and efficient manner. This avoids sudden jolts and possible damage. Once the obstruction is passed, the plough body automatically returns to the correct ploughing depth.

Safety compliance

With today's demands for higher output, both tractor and plough are expected to perform quicker than ever. This makes more arduous demands on the equipment, particularly on the safety systems designed to protect tractors, ploughs and drivers against the dangers encountered whenever the plough meets hidden obstructions in the ground. The Kverneland Auto-Reset system guaranties this safety high standars requirements.

Adaptable to varying soil conditions

Depending of the type of soil all Kverneland ploughs can be equipped with different leaf springs packages. For soft soils, a normal spring with 5 leaves is the best choice to obtain the perfect ploughing in stony conditions. Today, most Kverneland ploughs are delivered with the Heavy Duty springs package (HD) with 7 leaves. This will perform well in most conditions. If the soil is very hard and stony - a double leaf spring package is recommended.

Extra leaves when needed

The standard Auto-Reset system includes 7 Kverneland heat treated springs (640Kp).

For heavier to extreme soil conditions, extra leaf springs are added for up to 1400kp.

The leaves are easily fixed with one central bolt only.

Individual body release !

The Kverneland mechanical Auto-Reset system enables very plough body to release independently. A quality ploughing is therefore guaranteed.

Minimum wear and high second hand value

Kverneland's Auto-Reset System is a quite simple construction that withstands the punishing forces year in, year out, with a minimum of maintenance. Save time and money !

Moreover, the Kverneland auto-reset system guarantees a longer life to the plough. When hitting an obstacle, the pressure on the point, frame, plough parts, decreases. The stress on Kverneland ploughs is therefore reduced. Consequently, second hand Kverneland ploughs sell at a higher value than competitors ploughs.

*by using an Hydraulic system, pressure would increase

Kverneland Heat Treatment Technology:

- more than 140 years of experience

- steels that withstand the toughest of conditions

- best robustness/weight ratio on the market

- for equivalent robustness, competitors would add more steel and therefore more weight, quicker wear, dissappointing ploughing results

Kverneland Steels:

- Benefits from less weight:

easier to pull/lower fuel consumption/lower lift requirement/reduced wear and stress for the tractor/more economical … - Benefits from more resistance:

minimum breakage/less maintenance/lower rotation for wearing parts/time saving/highest 2nd hand plough value/longer life for the plough/more economical…

Problems always happen when the plough is being used, when the work must be done!

A Kverneland plough is a peace mind!

More info: Kverneland Technology

Technical specifications

Technical specifications

Download brochure| Model | Ecomat | ||

|---|---|---|---|

| Interbody clearance cm | 65 | ||

| Head- stock | Nº 200 | ||

| Leg protection | Auto-reset | ||

| Working width cm | 30-50 | ||

| Underbeam clearance cm | 72 | ||

| No. of furrows | 6-8 | ||

| Weight (kg) | 3 | – | |

| Lift requirement (kg) | 3 | – |

Technical specifications

Technical specifications

Download brochureNo of furrows |

5 |

6 |

7 |

8 |

Working width |

1.50 - 2.50 m |

1,80 - 3,00 m |

2,10 - 3,50 m |

2,40 - 4,00 m |

Working width per body |

30 - 50 cm (12"-20") |

30 - 50 cm (12"-20") |

30 - 50 cm (12"-20") |

30 - 50 cm (12"-20") |

Working depth |

6 - 18 cm |

6 - 18 cm |

6 - 18 cm |

6 - 18 cm |

Interbody clearance cm |

65 cm |

65 cm |

65 cm |

65 cm |

Under beam clearance |

72 cm |

72 cm |

72 cm |

72 cm |