Kverneland Exacta TL GEOSPREAD iDC

To get a perfect spread pattern.

intelligent Disc Control with the TL GEOSPREAD iDC.

Highlights

- Automatic function on disc RPM

- intelligent Disc Control - independent disc speed left and right

- All adjustments are easily done via the AutosetApp

- Prevent overlap with the GEOSPREAD system

- Section control with 1 metre sections

- MULTIRATE: multiple rates within a working width

Description

The TL GEOSPREAD iDC uses automatic control of the advised disc speed independent from the tractor RPM. This results in a better spreading pattern and more equal distribution in the field. This means improved settings and accuracy for border spreading in all conditions. Due to the hydraulically driven discs there is no need to use a PTO shaft. The TL GEOSPREAD iDC spreader is ISOBUS compatible and AEF certified. The spreader can be operated in combination with the IsoMatch Tellus PRO, IsoMatch Tellus GO+ or any other ISOBUS compatible tractor terminal.

Highlights

- Automatic function on disc RPM.

- Integrated hydraulic driveline.

- Independent disc speed left and right for border spreading.

- All adjustments are easily done via the AutosetApp.

- Border spreading for all type of fertiliser and all working widths.

- ISOBUS compatible and AEF certified.

- Possible in combination with IsoMatch GEOCONTROL.

Features

Features

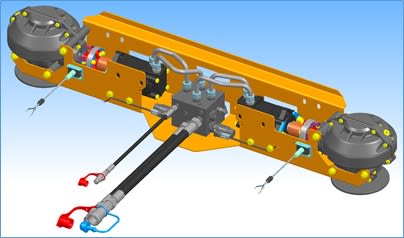

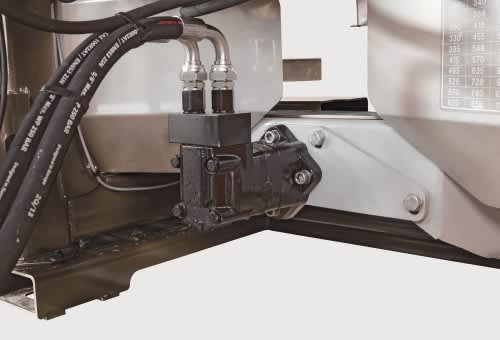

- iDC technology is a combination of an intuitive software with an integrated hydraulic driveline composed of a load sensing manifold link to two 80 cc hydraulic motors.

- Each hydraulic motor is equipped with a speed sensor which enables the hydraulic manifold to steer very precisely the hydraulic flow to each motor in order to adapt the disc speed for optimal precision in spreading.

- The intuitive and easy to use user interface allows the operator to have a clear view on each disc speed. It enables to save all the spreader settings for each fertiliser including the disc speed when spreading full width or when using an ExactLine border spreading device.

- The load sensing hydraulic drive allows the tractor to run at a lower engine RPM, which reduces fuel consumption and increases driver comfort. The spreader only takes the oil it needs from the tractor, which increases the lifetime of both the pump and oil.

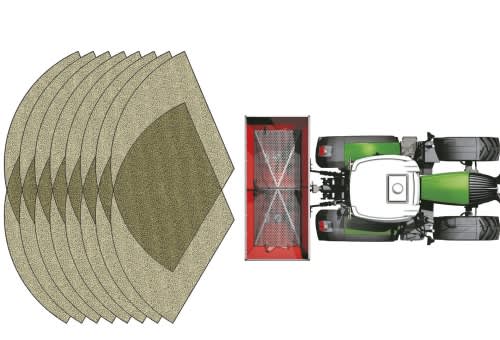

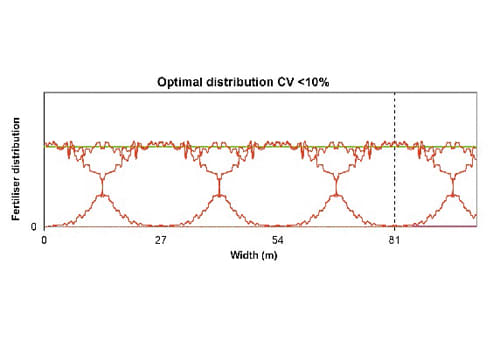

When running IsoMatch GEOCONTROL in addition to GEOSPREAD you can set the Exacta CL/TL/TLX GEOSPREAD (iDC) more accurately. The working width will automatically be adjusted to suit the overlap and coverage using a GPS positioning system. For example, when driving in a wedged or irregular shaped field, GEOSPREAD will start to decrease the working width step by step. GEOSPREAD is using the section control function of the IsoMatch GEOCONTROL software which is in the IsoMatch Tellus PRO or IsoMatch Tellus GO+ terminal. The spreader working width is divided into a minimum of 1 metre sections (max. 45 sections on TLX GEOSPREAD (iDC), max. 54 sections on TL GEOSPREAD (iDC) and max. 33 sections on CL GEOSPREAD). Not only the spreading width is adjusted, the application rate (kg/min) is also adjusted automatically to match the revised spreading width. This unique combination of working width and application rate adjustment makes the GEOSPREAD system extremely accurate, with minimum influence on the coefficient of variation of the spread pattern .

The Advantages:

- Quick and accurate spreading, due to the actuators being directly connected to the discharge point. No linkages.

- Automatic, in-field, disc RPM management to maintain a perfect spreading pattern and optimise border spreading in combination with the ExactLine.

- Section control with 1 metre sections (depending on the terminal functionality)

- Easy operation; no need to step off the tractor to adjust the working width

- 100% ISOBUS compatible for easy operation

- Automatic start/stop with GPS on headlands possible

- The Kverneland weighing spreader range is 100% ISOBUS compatible as standard, which means easy plug and play with the IsoMatch Tellus GO+ or PRO or an other AEF certified terminal.

- The GEOSPREAD spreader range is equipped with an user interface (Generation 3 electronics) on the control terminal with an easy navigation structure, intuitive layout and guarantees optimal user friendliness. Features includes: pre-sets to save different fertiliser types, easy filling mode including limit warning, easier service and diagnostics and support of a digital spirit level to be able to level the spreader with the hydraulic top link from the tractor cab. Operators will be fully prepared for the future of spreading.

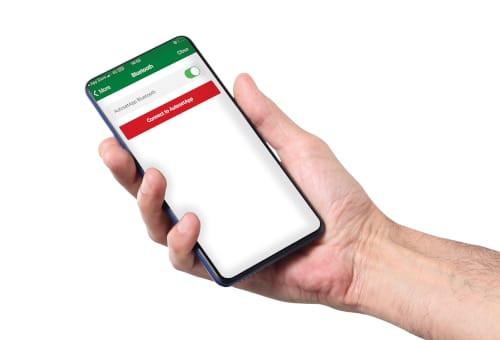

With the AutosetApp you have always the most up to date settings for your weighing spreader available. There are two ways to make use of the AutosetApp.

Exacta-CL/TL/TLX GEOSPREAD in combination with Kverneland Sync

Via the AutosetApp functionality within the Kverneland SpreadApp you can set-up your GEOSPREAD spreader in combination with a Kverneland Sync, via your mobile device.

Through the Bluetooth connection, operators can seamlessly connect the GEOSPREAD spreader to a mobile device, such as smartphone or tablet, using the AutosetApp functionality. This allows for the efficient transfer of spreader settings and presets directly from the mobile device to the spreader.

The benefits of this connectivity include error-free storage and transfer of spreading jobs. Additionally, the integrated filling calculator provides an exact measurement of the fertiliser needed to complete the spreading job, while real-time weight updates in the hopper are displayed directly on the App during filling, improving efficiency and accuracy.

Exacta-CL EW/CL W PRO/TL and all GEOSPREAD models without Kverneland Sync

The AutosetApp is an App (software application) that is also available on the IsoMatch Tellus PRO or IsoMatch Tellus GO+ terminal. The AutosetApp is standard integrated into the IsoMatch GEOCONTROL software. This App connects the terminal directly with the GEOSPREAD weighing spreader and will automatically adjust the spreader according to the settings entered into the App. The AutosetApp will also work in combination with the CL-EW, W PRO and TL, with the exception being for those spreaders the discharge point (letter setting) still needs to be adjusted manually on the spreader itself.

For easy and cost effective spreading

MULTIRATE (Variable Rate Application) applies multiple rates within a working width.

In order to spread the right amount of fertiliser at a specific place in a field there is a need to have a different rate within the working width. Depending on the field variation and the size of the grid of the variable application map, input of 2, 4, 6 or 8 rate sections can be used. This means a more accurate application of nutrients to have a better nutrient efficiency, better yield and reduce costs.

With a Kverneland GEOSPREAD spreader you invest in 100% ISOBUS compatibility for easy plug and play with the IsoMatch Tellus PRO or any other AEF certified terminal. In just some steps with this combination you are ready to use MULTIRATE. You have to convert a satellite or soil map into an ISO-XML file. Download the Variable Rate Map into the terminal and you are ready to spread with MULTIRATE with 2 up to 8 rates.

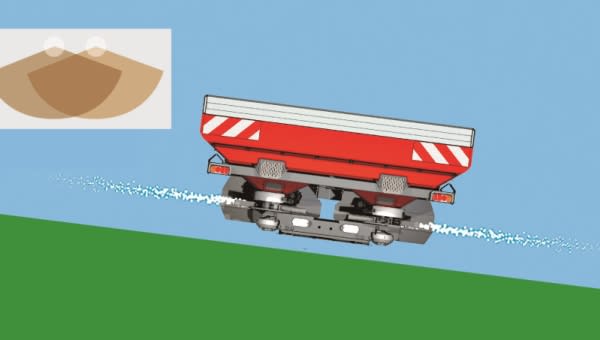

- No impact, no fragmentation, no dust: Central release point, smooth acceleration and centrifugal force accelerates fertiliser up to disc speed before it reaches the vane.

- Accurate spreading pattern: A double overlap spreading pattern gives unrivalled accuracy. The 8 vanes per discs are ensuring a continous flow of fertiliser to the field. This is important for high capacity spreading and forward speed.

- Minimal wind influence, maximum tolerance: Flat discs and a horizontal flow of fertiliser give a symmetrical spreading pattern.

- Consistent spreading pattern: Eight vanes per disc, eight sectors per revolution give an equal distribution. Double overlap spreading pattern.

- Guaranteed accuracy on slopes: guaranteed accuracy on slopes. The fertiliser always contacts the vanes at the same point, also on slopes and travels the complete length of the vane.

- Continuous dynamic "online - calibration" with high frequency communication signal.

- Kvernelands unique reference sensor technology: all negative influences are automatically corrected and eliminated, ensuring utmost spreading accuracy even on hill sides. The Kverneland reference sensor gives you absolute accuracy, because every kilo counts!

- Load cells in combination with the unique reference sensor:

- Auto calibrating and continuous weighing system

- Automatic correction on slopes

- Automatic correction of shocks, even on rough terrain

- Automatic speed related dosing system

- No calibration test needed

- Highest accuracy in all conditions: even spreading quality guaranteed! Save costs and increase quality!

- Kverneland offers the ExactLine system or manual/hydraulic border spreading plate for border spreading. The ExactLine can be accurately set for all types of fertiliser and for all working widths. Operation is easy, no need to leave the tractor seat. For the CL GEOSPREAD, HL, TL TLX GEOSPREAD (iDC) models the ExactLine can even be fitted on the left- and right-hand side of the spreader.

- With one-side boundary spreading the tractor is driven approximately 2 metres from the field border.

- With boundary track spreading the tractor is driving in the first tramline and is spreading to the border. The distance to the border is the half of the working width.

- The Border Spreading Indicator (BSI) on the standard weighing spreaders (Exacta CL EW, Exacta CL W PRO, Exacta TL) indicates which border spreading device is active. For the GEOSPREAD machines this is integrated in the electronics and the active device will be displayed on the control terminal in the cab.

- A Central Hydraulic Drive is as option available for spreading without PTO shaft, for the HL, TL and TL/TLX GEOSPREAD.

- Easy to assemble aluminium hopper extensions are available to increase hopper capacity.

- An easy to fold in and out hopper cover is as option available. Simple to fit! It can be the manual folded hopper cover or the electrical version which can be controlled from the tractor cab.

- Left/right shut off valve for spreading at half working widths is optional available.

- To ensure a consistent flow when spreading low quantities, the CentreFlow system is equipped with a fine application kit. Ideal for spreading low quantities, seeds and slug pellets.

- Delta shaped heavy duty grids are standard equipment of the Exacta HL, TL, TL/TLX GEOSPREAD (iDC) spreaders.

- Central gear box with 2 input shafts for high and low disc speed settings is standard equipment of the HL, TL, TL/TLX GEOSPREAD (iDC) spreaders.

- Hopper emptying kit is optional available to easy get the last fertiliser out of your hopper.

- Easy calibration is done with the optional calibration container.

- Long lifetime LED lighting set is standard equipment for the HL, TL, TL/TLX GEOSPREAD (iDC).

- The mud guards (option) protect the spreading disc against mud, water etc.

Increase capacity

The combination of a front and rear spreader will not only increase the total hopper capacity up to 6,000 or 7,000l, but also, it makes it possible to spread two different applications in one pass. This saves time and labour due to less passes, and also reduces soil damage.

There is a perfect weight balance with a (smaller) spreader on the front and rear, which means less ground pressure or soil compaction which can be especially helpful in wet conditions. In case there is no PTO shaft available at the front of the tractor, the central hydraulic driveline on the GEOSPREAD spreaders can be used.

With a front lighting set available as an option, the road lighting turns on the correct side if the spreader is located in the front of the tractor.

Accurate spreading pattern

Spreading two different fertilisers at the same time in one pass will increase nutrition accuracy. Two different fertiliser types, with different physical properties, can be applied with a correct setting to have a perfect spreading pattern. The result is an increased yield and cost savings on fertiliser.

Different combinations

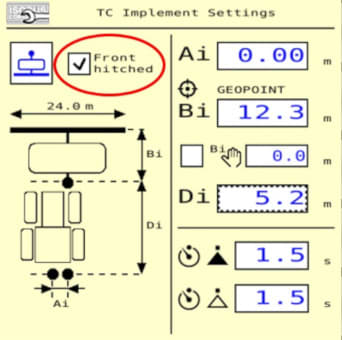

All Kverneland spreader models, even with a different hopper capacity, can be combined in the front and the rear. However for the models where there is no ExactLine border device available for the left hand side spreading, there is a limitation in border spreading on the headland. In the Task Control (TC) on the ISOBUS terminal there is the possibility to select the front spreader and to enter the correct settings for the front spreader.

Increase efficiency

With the front and rear spreader combination and two ISOBUS terminals connected, much more is possible to save costs and increase efficiency! To minimise overlap, section control will automatically switch on and off sections on both spreaders. With the variable rate application on all the Kverneland GEOSPREAD spreaders it is possible to automatically adjust the application rate separately from the front and rear spreader. For even more precision, MULTIRATE applies multiple rates within a working width, independently from the front and rear spreader.

High quality vanes is the best choice to get maximum performance and output out of your working day.

Increased use of very hard fertilisers with sharp edges at high flow rates will shorten the lifetime of the vanes. Worn out vanes are creating an unreliable spreading pattern, causing uneven nutrient distribution and potential yield loss.

XHD wearing resistant vanes stand for a long lifte time and reliable machine. The surface coating of the lift vanes was introduced for this purpose.

The XHD lift vanes are made out of standard Duplex stainless steel, treated with Chromium carbide coating layer to increase their wearing resistance. The Chromium carbide is an extremely hard and corrosion resistant material. It's heated to very high temperatures and sprayed on the vane to create a protective layer. The Chromium carbide increases the wearing resistance, but has no influence on the spreading pattern. The XHD lift vanes provide a high quality spreading pattern and durability for the farmer.

Kverneland Spreader Competence Centre

The Kverneland Exacta disc spreaders are known worldwide for their reliability, ease of operation and outstanding precision in all conditions. This is the result of many years of practical experience, research and testing. A fertiliser spreader can only be set accurately based on the physical properties of the fertiliser and using the corresponding settings provided by the manufacturer.

The spreader Competence Centre is using the most modern technology available in hard and software, allowing the measurement of complete overlap patterns in 3D. Instead of only measuring the spreading pattern in one line corresponding to the working width, this technology creates a full pattern showing a complete 3D spreading profile of the fertiliser.

Get direct access to the spreading charts

Exact advice for each Kverneland Exacta spreader at any working width, application rate and driving speed. Direct access to most recent test results at: www.kvernelandspreadingcharts.com

Or download the SpreadApp which is available on the App store and Google Play

Kverneland Sync and GEOSPREAD Spreaders

Kverneland Sync is the essential connectivity gateway for your GEOSPREAD spreader, enabling continuous data transfer to IsoMatch FarmCentre and Kverneland ServiceCentre. Data flow supports seamless task management, real-time monitoring and efficient remote diagnostics - minimizing downtime and enhancing overall performance.

Kverneland Spreading Charts App

The Kverneland SpreadApp on a mobile device serves as a powerful tool for precise fertiliser settings. With a bluetooth connection and Sync, users can seamlessly connect the GEOSPREAD spreader to a mobile device, using the AutosetApp functionality. Users can select their spreader model, put in their fertiliser properties, receive expert recommendations for the best spreader settings and send the spreader settings directly from the mobile device to the spreader. The App is available on iOS and Android devices.

Remote Service - Minimize Downtime

Thanks to the remote diagnostics, Kverneland Sync allows technicians to analyze data from your ISOBUS spreader via Kverneland ServiceCentre, enabling quick troubleshooting from a distance to reduce downtime in case of an issue. See how it works: https://www.youtube.com/watch?v=eTPpsI5YPZc

Technical specifications

Technical specifications

Download brochure| Exacta TL GEOSPREAD iDC | |||||

|---|---|---|---|---|---|

| Hopper capacity (l) | 1875 | 2550 | 3225 | 3900 | |

| Filling height (cm) | 119 | 138 | 157 | 176 | |

| Width (cm) | 290 | 290 | 290 | 290 | |

| Filling width (cm) | 284 | 284 | 284 | 284 | |

| Empty weight (kg) | 700 | 730 | 760 | 790 | |

| Spread width (m) | 12-54* | 12-54* | 12-54* | 12-54* | |

| Output (kg/min) | 10-320 | 10-320 | 10-320 | 10-320 | |

| Controls | ISOBUS | ISOBUS | ISOBUS | ISOBUS | |

| Hydraulic drive line | Standard | Standard | Standard | Standard | |

| LED lighting set | Standard | Standard | Standard | Standard | |

| Border spreading plate | Option | Option | Option | Option | |

| ExactLine border spreading system | Option | Option | Option | Option |

*Dependent on type of fertiliser and vanes.

Technical specifications

Technical specifications

Download brochureHopper capacity (l) |

1875 |

2550 |

3225 |

3900 |

Filling height (cm) |

119 |

138 |

157 |

176 |

Width (cm) |

290 |

290 |

290 |

290 |

Filling width (cm) |

284 |

284 |

284 |

284 |

Empty weight (kg) |

700 |

730 |

760 |

790 |

Spread width (m) |

12 - 54* |

12 - 54* |

12 - 54* |

12 - 54* |

Output (kg/min) |

10 - 320 |

10 - 320 |

10 - 320 |

10 - 320 |

Controls |

ISOBUS |

ISOBUS |

ISOBUS |

ISOBUS |

Hydraulic drive line |

Standard |

Standard |

Standard |

Standard |

LED lighting set |

Standard |

Standard |

Standard |

Standard |

Border spreading plate |

Option |

Option |

Option |

Option |

ExactLine border spreading system |

Option |

Option |

Option |

Option |

* Depending on fertiliser type and type of vanes.

*Dependent on type of fertiliser and vanes.