e-drill

Seeder | Pneumatic Mounted Seed Drill

Time pressure in the autumn and spring ask for an efficient and versatile seed drill combination, like the Kverneland e-drill.

This integrated seed drill is efficient, precise and operator-friendly.

The advantages of this Pneumatic Mounted Seed Drill

- Reduced lifting power requirement

- Simple and reliable calibration with ELDOS

- Simple and independent depth adjustment

- Precise seed placement by CX-II coulters

Description

The range of Kverneland e-drill as integrated power harrow mounted seed drills allow active seed bed preparation, consolidation and precise seed placement in one pass. The proven concept and clear design of the e-drill maxi and e-drill compact, together with the high level of incorporated intelligent technology ensure precise and reliable performance.

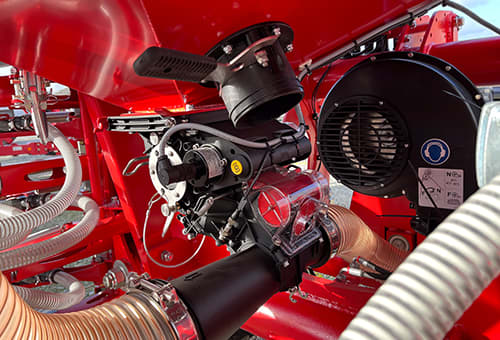

With the innovative pneumatic seed drill, the operator has maximum ease of use, from set-up and filling to operation and transport. The seed hopper is mounted directly on the three-point linkage of the Kverneland power harrow for a close centre of gravity and, therefore, reducing the requirement for lifting power.

Highlights

- Close centre of gravity for reduced lifting power requirement

- Simple and reliable calibration with electric-driven metering device ELDOS: self-monitoring and easily accessible

- Simple and independent depth adjustment of the power harrow and the coulterbar for even depth control and seed placement

- Precise seed placement by CX-II coulters

- Central depth and pressure adjustment of the following harrow

- Working lights inside and outside of the hopper allow safe use even in darkness

Features

Features

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

Flexibility is key!

The coulterbar can be easily coupled and uncoupled with a coupling hook similar to the front loader coupling. Track markers are attached to the power harrow. Therefore, the power harrow is ready for solo operation within short time. The coulterbar is attached with the Euro-Connection directly to the roller frame and can quickly and easily be hitched thanks to the readily accessible hydraulic and electronic interface.

The e-drill is exclusively designed to be combined with Kverneland power harrows.

- The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement.

- The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

- Due to the combination of the steel disc with a diameter of 325mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

- Up to 50kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface.

- An inter-row coulter spacing of 445mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions.

- The press wheels can be set in fixed, floating of lifted position in order to be able to adapt quickly to changing weather, soil or working conditions.

- The CX-II coulter is also available as light edition without press wheel which reduces the weight and length of the coulterbar. This will allow to operate the seeding combination also with lower lifting capacity of the tractor.

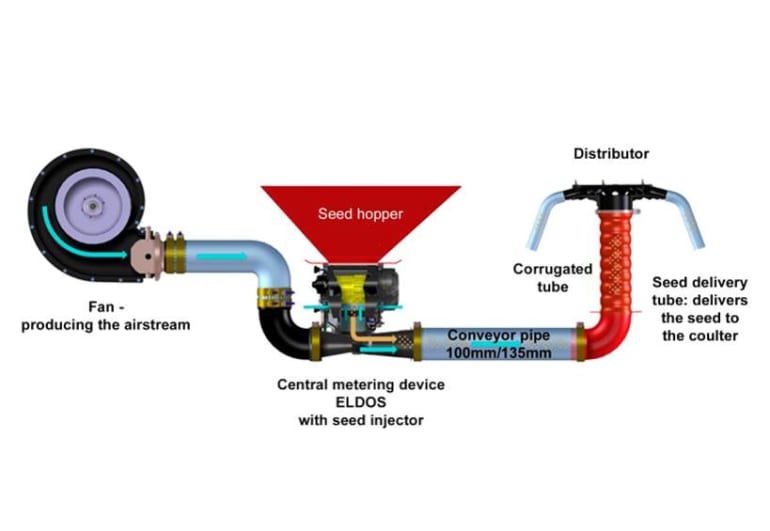

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

For the electronic control of the e-drill, a whole range of steering systems is available

Focus 3

Focus 3 is the new terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about ha, km/h monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

IsoMatch Tellus Go+

The multifunctional one-screen terminal has been developed for fast and simple control of all ISOBUS implements, giving the farmer a ‘customer made’ experience as it suits all needs for plain and efficient handling of farming machinery and tasks. IsoMatch Tellus Go+ is the farmer’s first step into Precision Farming. With the easy to use application, IsoMatch GEOCONTROL, it is possible to boost efficiency and save time and costs. The application includes Manual Guidance, Section Control and Variable Rate.

IsoMatch Tellus PRO

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

With this new terminal you can work all the way as a PRO. The maximum working range for the task controller IsoMatch GEOCONTROL is increased from 2 km to maximum 10 km from the starting point. Thus even extremely big fields are handled in a full professional way. The new high brightness screen increases operator comfort. Visibility is increased during the day and dimmed to just a glowing display in dark conditions.

For an extended scope of application, Kverneland has integrated the well-known Kverneland a-drill. This extra seeder with separate hopper and metering device will allow applying an additional sort of seeds/fertilizer all in one pass.

Sustainable and efficient

There are good reasons to promote the establishment of additional crops or to apply extra nutrients whilst seeding. An additional crop will suppress weed growth but not compete with the leading crop. The extra crop catches the mineral nitrogen in the soil as well as air nitrogen, when mixing with leguminous plants, transforming it into organic nitrogen. Thus, nitrogen will still be available for the next crops. Fertilisers are applied most precisely to support plant growth, specifically during youth development avoiding its wash-out into groundwater.

Wide scope of application

The scope of application and possible variations for this integrated seed drill are manifold:

With the e-drill compact/maxi, one type of material is precisely deposited by the CX-II coulter; whereas the second material is applied via the baffle plate from the integrated a-drill into the soil flow of the following harrow:

1. 2 types of material in one pass: 1 type of seed (e.g. rape) plus slug pellets

2. 2 types of seeds: e.g. barley by the coulter plus clover/grass via the following harrow

The e-drill maxi plus, as the combined grain and fertiliser model of the power harrow mounted seed drill, is already equipped with a divided hopper with adjustable ratio of 60:40, 70:30 or 100:0 and two independently working metering devices.

Here, two sorts of material are precisely deposited by the double-entry coulter CX-II (2 distribution heads); whereas the third sort of material is applied via the baffle plate of the integrated a-drill into the soil flow of the following harrow:

- 3 sorts of material in one pass: 1 sort of seed (e.g. wheat/barley) plus fertiliser in the sowing rows plus slug pellets via the following harrow

- 3 sorts of material in one pass: 1 sort of seed (e.g. wheat/barley) plus fertilser in the sowing row plus 1 sort of seed (e.g. clover) via the following harrow

- 3 sorts of material in one pass: 2 sorts of seed in different sowing rows (e.g. beans & rape seed) plus slug pellets via the following harrow

- 3 sorts of material in one pass: 2 sorts of seed in the sowing row (e.g. beans & rye) plus 1 sort of seed (e.g. clover) via the following harrow

Advantages

- Utmost efficiency and cost saving by combined application of various sorts of seeds plus/or fertilizer all in one pass

- Encouraged root development

- Reduced risk of erosion

- Increased sustainability

- Increased biodiversity and humus content

- The metering device ELDOS accurately measures the required volume of seed by the distinctive rotor and discharges it into the seed injector where is is mixed with the air stream and then conveyed through the diffusor tube and the seed delivery hoses to the coulters.

- The distribution head is mounted in a protected position inside the seed hopper.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

- The CX-II disc coulter from Kverneland not only guarantees smoother running but also exact seed placement.

- The flatter cutting angle of only 5.4° of the steel disc requires less pulling power to reach a constant seeding depth of up to 6cm.

- Due to the combination of the steel disc with a diameter of 325mm and the flexible plastic disc, there is no need for independent scrapers, saving the cost for expensive wearing parts. In addition the coulter is completely maintenance-free!

- Up to 50kg coulter pressure can be achieved by a pre-loaded spring. Safe operation is ensured when working with high working speeds and high quantities of plant residues on the soil surface.

- An inter-row coulter spacing of 445mm for maximum clearance and the following press wheel (standard equipment) ensure an optimum seed/soil contact in all conditions.

- The press wheels can be set in fixed, floating of lifted position in order to be able to adapt quickly to changing weather, soil or working conditions.

- The CX-II coulter is also available as light edition without press wheel which reduces the weight and length of the coulterbar. This will allow to operate the seeding combination also with lower lifting capacity of the tractor.

For an extended scope of application, Kverneland has integrated the well-known Kverneland a-drill. This extra seeder with separate hopper and metering device will allow applying an additional sort of seeds/fertilizer all in one pass.

Sustainable and efficient

There are good reasons to promote the establishment of additional crops or to apply extra nutrients whilst seeding. An additional crop will suppress weed growth but not compete with the leading crop. The extra crop catches the mineral nitrogen in the soil as well as air nitrogen, when mixing with leguminous plants, transforming it into organic nitrogen. Thus, nitrogen will still be available for the next crops. Fertilisers are applied most precisely to support plant growth, specifically during youth development avoiding its wash-out into groundwater.

Wide scope of application

The scope of application and possible variations for this integrated seed drill are manifold:

With the e-drill compact/maxi, one type of material is precisely deposited by the CX-II coulter; whereas the second material is applied via the baffle plate from the integrated a-drill into the soil flow of the following harrow:

1. 2 types of material in one pass: 1 type of seed (e.g. rape) plus slug pellets

2. 2 types of seeds: e.g. barley by the coulter plus clover/grass via the following harrow

The e-drill maxi plus, as the combined grain and fertiliser model of the power harrow mounted seed drill, is already equipped with a divided hopper with adjustable ratio of 60:40, 70:30 or 100:0 and two independently working metering devices.

Here, two sorts of material are precisely deposited by the double-entry coulter CX-II (2 distribution heads); whereas the third sort of material is applied via the baffle plate of the integrated a-drill into the soil flow of the following harrow:

- 3 sorts of material in one pass: 1 sort of seed (e.g. wheat/barley) plus fertiliser in the sowing rows plus slug pellets via the following harrow

- 3 sorts of material in one pass: 1 sort of seed (e.g. wheat/barley) plus fertilser in the sowing row plus 1 sort of seed (e.g. clover) via the following harrow

- 3 sorts of material in one pass: 2 sorts of seed in different sowing rows (e.g. beans & rape seed) plus slug pellets via the following harrow

- 3 sorts of material in one pass: 2 sorts of seed in the sowing row (e.g. beans & rye) plus 1 sort of seed (e.g. clover) via the following harrow

Advantages

- Utmost efficiency and cost saving by combined application of various sorts of seeds plus/or fertilizer all in one pass

- Encouraged root development

- Reduced risk of erosion

- Increased sustainability

- Increased biodiversity and humus content

Flexibility is key!

The coulterbar can be easily coupled and uncoupled with a coupling hook similar to the front loader coupling. Track markers are attached to the power harrow. Therefore, the power harrow is ready for solo operation within short time. The coulterbar is attached with the Euro-Connection directly to the roller frame and can quickly and easily be hitched thanks to the readily accessible hydraulic and electronic interface.

The e-drill is exclusively designed to be combined with Kverneland power harrows.

For the electronic control of the e-drill, a whole range of steering systems is available

Focus 3

Focus 3 is the new terminal steering the e-bas system which features hopper low level sensor, various tramline systems, information about ha, km/h monitoring of fan speed, pre-emergence marker, seed rate adjustments. Focus 3 is not ISOBUS compatible.

IsoMatch Tellus Go+

The multifunctional one-screen terminal has been developed for fast and simple control of all ISOBUS implements, giving the farmer a ‘customer made’ experience as it suits all needs for plain and efficient handling of farming machinery and tasks. IsoMatch Tellus Go+ is the farmer’s first step into Precision Farming. With the easy to use application, IsoMatch GEOCONTROL, it is possible to boost efficiency and save time and costs. The application includes Manual Guidance, Section Control and Variable Rate.

IsoMatch Tellus PRO

IsoMatch Tellus PRO is the centre for connecting all ISOBUS machines and a platform for running precision farming applications. It offers everything a farmer needs to get the maximum out of his machines and crops, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives the farmer the opportunity to view and control two machines and processes simultaneously.

With this new terminal you can work all the way as a PRO. The maximum working range for the task controller IsoMatch GEOCONTROL is increased from 2 km to maximum 10 km from the starting point. Thus even extremely big fields are handled in a full professional way. The new high brightness screen increases operator comfort. Visibility is increased during the day and dimmed to just a glowing display in dark conditions.

Technical specifications

Technical specifications

Download brochure| Model | e-drill compact | e-drill compact | e-drill compact | e-drill maxi | e-drill maxi | e-drill maxi | |

|---|---|---|---|---|---|---|---|

| Maschine type | cultivator mounted | cultivator mounted | cultivator mounted | cultivator mounted | cultivator mounted | cultivator mounted | |

| Working width (m) | 3.0 | 3.5 | 4.0 | 3.0 | 3.5 | 4.0 | |

| Transport width (m) | 3.0 | 3.5 | 4.0 | 3.0 | 3.5 | 4.0 | |

| Hopper capacity (l) | 1,100 | 1,100 | 1,100 | 1,600 | 1,600 | 1,600 | |

| Hopper extensions (l) | 300 | 300 | 300 | 400 | 400 | 400 | |

| Quick emptying chute | Standard | Standard | Standard | Standard | Standard | Standard | |

| Low level sensor | Standard | Standard | Standard | Standard | Standard | Standard | |

| Drive 1000 rpm | Option | Option | Option | Option | Option | Option | |

| Hydraulic fan drive | Standard | Standard | Standard | Standard | Standard | Standard | |

| ELDOS electric driven metering device (No.) | Standard (1) | Standard (1) | Standard (1) | Standard (1) | Standard (1) | Standard (1) | |

| Micro metering | Standard | Standard | Standard | Standard | Standard | Standard | |

| e-bas electronic (Focus 3) | Standard | Standard | Standard | Standard | Standard | Standard | |

| e-com electronic (IsoMatch Tellus Pro/ Tellus GO) | Option | Option | Option | Option | Option | Option | |

| Metering device control | Standard | Standard | Standard | Standard | Standard | Standard | |

| Seed rate adjustment | Standard | Standard | Standard | Standard | Standard | Standard | |

| Seed quantity (min. - max.) | 1 - 400kg/ha | 1 - 400kg/ha | 1 - 400kg/ha | 1 - 400kg/ha | 1 - 400kg/ha | 1 - 400kg/ha | |

| Shut-off valves for tramlines | Option | Option | Option | Option | Option | Option | |

| Electric half-width shut-off | Option | Option | Option | Option | Option | Option | |

| Pre-emergence marker | Option | Option | Option | Option | Option | Option | |

| Vertical hydr. folding track marker with notched disc | Option | Option | Option | Option | Option | Option | |

| No. of coulters 12.5cm distance (standard) | 24 | 28 | 32 | 24 | 28 | 32 | |

| No. of coulters 15cm distance (option) | 20 | 24 | 26 | 20 | 24 | 26 | |

| CX-II coulter incl. press wheel | Standard | Standard | Standard | Standard | Standard | Standard | |

| CX-II coulter disc Ø (mm) | 325 | 325 | 325 | 325 | 325 | 325 | |

| CX-II coulter double entry (DF1 / Plus) | Option | Option | Option | Option | Option | Option | |

| Press wheel Ø (mm) | 250 x 42 | 250 x 42 | 250 x 42 | 250 x 42 | 250 x 42 | 250 x 42 | |

| Coulter pressure CX-II disc coulter (kg) | 5 - 50 | 5 - 50 | 5 - 50 | 5 - 50 | 5 - 50 | 5 - 50 | |

| Mechanic coulter pressure adjustment by crank | Standard | Standard | Standard | Standard | Standard | Standard | |

| Hydraulic coulter pressure adjustment | Option | Option | Option | Option | Option | Option | |

| Mechanic central seed depth setting by spindle | Standard | Standard | Standard | Standard | Standard | Standard | |

| Hydraulic central seed depth setting by two outer cylinder incl. coulter bar lifting | Option | Option | Option | Option | Option | Option | |

| EURO-CONNECTION | Standard | Standard | Standard | Standard | Standard | Standard | |

| S-tine harrow (10mm) | Option | Option | Option | Option | Option | Option | |

| Calibration set | Standard | Standard | Standard | Standard | Standard | Standard | |

| Loading step / Platform | Standard | Standard | Standard | Standard | Standard | Standard | |

| Lighting equipment | (LED) | (LED) | (LED) | (LED) | (LED) | (LED) | |

| Oil charge hydr. fan (l/min) | 30 | 30 | 30 | 30 | 30 | 30 | |

| Min. power requirement (HP/kW) | 100 / 74 | 115 / 85 | 125 / 92 | 130 / 96 | 140 / 103 | 150 / 110 | |

| Weight **(kg) with coulters | 1,120 | 1,270 | 1,350 | 1,220 | 1,300 | 1,390 |

** Weight without power harrower

Technical specifications

Technical specifications

Download brochureModel |

e-drill compact |

e-drill maxi |

Working width |

3.0 / 3.5 / 4.0 |

3.0 / 3.5 / 4.0 |

Hopper capacity (l) |

1100 - 1400 |

1600 - 2000 |

No. of coulters (12.5cm distance - standard) |

24 / 28 / 32 |

24 / 28 / 32 |

No. of coulters |

20 / 24 / 26 |

20 / 24 / 26 |

Weight (kg) |

1120 / 1270 / 1350 |

1220 / 1300 / 1390 |

** Weight without power harrower