KVERNELAND iXtrack T6

Sprayer | Trailed Sprayer

For maximum productivity and performance.

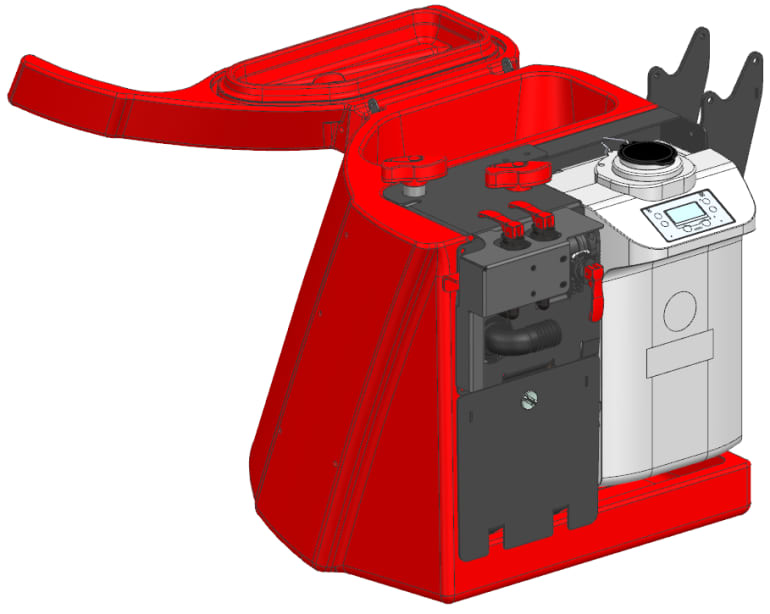

The Kverneland iXtrack T6 is designed for maximum performance and productivity in combination with precise, easy and cost effective spraying.

The advantages of this Trailed Sprayer

- Low centre of gravity with compact tank dimensions

- iXspray for a user friendly operation

- Boom Guide: automatic boom height control system

- iXflow-E high pressure recirculation system

- Connect your machine with IsoMatch FarmCentre

Description

The nominal tank volume of the iXtrack T6 goes up to 7600 litres. The Kverneland sprayer technology ensures that spraying is done in the most easiest and most efficient way. The iXtrack T6 is fully suspended that means a suspended drawbar, wheel axle and parallelogram. Also in transport position, improving driver comfort and stability in all conditions. The iXspray software with intuitive touch interface guarantees user friendly operation. A choice can be made between manual control of the EasySet control panel, iXclean Comfort for semi-automatic control or iXclean Pro fully automatic valve management system. The iXflow spray line recirculation system is available with pneumatic nozzle control or as iXflow-E with electrically controlled nozzles for individual nozzle control.

Highlights

- Low centre of gravity, compact dimensions and special tank design.

- iXspray means an intuitive user interface and user friendly operation that ensures that spraying is done in the most easy and efficient way.

- The smooth, suspended parallelogram combines optimal stability with soft boom balancing and limited vertical movement to minimise spray height deviations.

- Easy plug and play with the IsoMatch Tellus GO+ or PRO or any other AEF certified terminal.

- The position of the tanks, hoses, valves and drains is optimised to minimise rest liquid.

- Connect yourself easily to your machine with IsoMatch FarmCentre, IsoMatch TopService or IsoMatch TopRemote.

Features

Features

Your Sprayer, Always Connected with Kverneland Sync

Kverneland Sync ensures your ISOBUS sprayer remains fully connected, facilitating continuous data transfer to IsoMatch FarmCentre and Kverneland ServiceCentre. Sync enables real-time monitoring, efficient task management and remote diagnostics, allowing technicians to swiftly analyze and resolve electronic issues, minimizing downtime and maintaining application consistency.

Optimized Task Management and Field Documentation

With Kverneland Sync, users have seamless access to key spraying data through IsoMatch FarmCentre, which supports comprehensive task documentation, application tracking and detailed performance metrics. This connectivity aids in planning, reporting and accurate record-keeping, allowing users to view spray rates, spray patterns and field coverage for enhanced field management.

Enhanced Security and Connectivity

Kverneland Sync also provides geofencing features with real-time location tracking. The Sync accumulator ensures continued traceability, even when the sprayer is disconnected from the tractor. Kverneland Sync and IsoMatch FarmCentre create an integrated solution that optimises efficiency and ensures traceability. By collecting data fromt he sprayer we are able to analyse the best spraying conditions and empowers precision and efficiency of the next spraying operation.

The DAT camera technology on the Kverneland sprayer range is a precision tool which supports farmers and contractors in patch spraying and with that a reduction of spray liquid.

The DAT Ecopatch recognises and categorises weeds in fields with wheat, cereals and oil seed rape. When weeds are recognised by the camera, a signal is sent to the Kverneland field sprayer and the appropriate nozzles are activated, up until a speed of 10 km/hr.

The system is built on pragmatism, relying on the agronomic principle of weeds growing in patches, which means a cost-effective solution.

Using the DAT Ecopatch on a Kverneland sprayer is easy. Just activate the system by clicking a button on the IsoMatch Tellus PRO or GO+ or any other AEF certified terminal and the combination is ready to go. Automatically, the weed will be recognised and the nozzles are turned on and off.

The data, such as as-applied data and weed heat maps will be directly available and can be used directly in combination with for example IsoMatch FarmCentre for further analysis.

With the DAT camera technology on a Kverneland sprayer savings on spray liquid up to 58%* can be reached. Additionally, the non-sprayed areas will preserve healthy crop from unnecessary treatment, which means less crop damage and another benefit is the increased capacity, as more hectares or fields can be covered with one tank of spray liquid.

*2024 DAT trials in canola

The HSS spray boom combines a minimum of weight with maximum strength and stability. Special hardened Domex steel gives the spray boom a long lasting heavy duty high quality reputation. The aluminium bonding instead of welding of the HSA spray boom range provides a weight saving and gives remarkable strength.

HSS Spray Boom

The HSS spray boom is designed for professional use. The triangular construction provides perfect integration of the stainless steel spray lines, nozzles and nozzle holders and the optimal hose routing where all is well protected. Working widths from 18 up to 40 metres with a variation in different section lengths offer the sprayer adapted to customer demands!

HSA Spray Boom

The HSA spray boom offers efficient protection of the nozzle holders within the bottom profile. This profile is designed for easy cleaning and much more. With no sharp angles, no liquid and residues can be trapped. The anodised surface protects against corrosion and scratches.

Compact and Stable

In transport position the HSA and HSS spray boom fold away nicely over the patented tank design and far away from the tractor cab. This results in a transport width of 2.55m and a height below 4m that together with the low gravity point provides excellent stability on the road, as well in the field.

The iXtrack T series are 100% ISOBUS compatible as standard, which means easy plug and play with the IsoMatch Tellus GO+ or PRO or any other AEF certified terminal. The innovative iXspray hardware and software with intuitive touch interface guarantees an user friendly operation of the sprayer. iXspray is full of nice features to make the operators life easy, save time and avoid mistakes in a busy working season, for example pre-sets for spray jobs and boom configuration can be configured easily.

IsoMatch Grip

The IsoMatch Grip adds control to your fingertips for easy control of the sprayer. From 1 up to 44 functions over 4 modes can be programmed freely by the operator. So you can start with basic functionalities and add other functionalities later on demand. Due to the ISOBUS AUX-N functionality the IsoMatch Grip can also be used to control other implements.

IsoMatch GEOCONTROL

The combination of IsoMatch GEOCONTROL and GPS allows the operator to reduce overlap and over dosing, to increase crop quality and save costs. All this in combination with even high flow rates, because there is no impact on the section length, no loss of pressure or an unequal flow between sections. IsoMatch GEOCONTROL application fulfils the need in terms of easy, smart and efficient farming, by providing the use of automatic section control and variable rate applications.

Easy hitching

The iXtrack T6 is available in combination with a low linkage.

Maximum Steering Possibilities

The iXtrack T6 offers maximum user friendliness and comfort by having a steering axle which contributes to excellent stability in different field conditions. The track width can be changed from 1.80m to 2.25 metres. This ensures maximum steering possibilities with a tight turning radius.

Smooth and Suspended

The iXtrack T series is equipped with a smooth, suspended parallogram that is active when in the field and in transport. The parallelogram combines optimal stability with soft boom balancing and limited vertical movement to minimise spray height deviations, securing correct crop coverage.

ErgoDrive Headland Management System

ErgoDrive headland management is standard equipment for the iXtrack T6. ErgoDrive assists the operator on the headland turns. It is activated by simply switching ON or OFF and ErgoDrive controls all the necessary actions, while the operator can focus on driving safely.

iXclean

ENFO priming and rinsing is standard on all Kverneland spray computers. Before spraying starts the spray lines are filled with chemicals exactly up to the nozzle by automatic shut off. After finishing or interruption, crop protection agents are automatically flushed out of the spray lines with a minimum of clean water consumption. This ENFO technology optimizes filling and cleaning of the spray lines. Accurate application, no waste of products and saving water are the benefit for the environment.

iXclean Comfort

iXclean Comfort is a semi-automatic valve control system. The combination of an electrical level indicator and suction valve provides operator comfort and accuracy; automatic filling stops when the programmed level is reached, and remote control of all ENFO rinising and priming functions are carried out from the cab! Simple prime the spray lines before you start and rinse them afterwards.

iXclean Pro

iXclean Pro is an advanced solution with fully automatic, electric valve management. It means all functions can be controlled from the cab. Switching between filling, agitation, spraying, diluting, priming, rinsing and tank cleaning, is extremely easy: just push the button! In addition iXclean Pro offers also a fully automatic multi-step rinsing and cleaning program with triple dilution for the entire sprayer. Pushing one button a comprehensive cleaning process including all lines will start. It is so thorough, that residue levels after automated cleaning are below 1%.

iXflow-E

iXflow-E is the high pressure recirculation system with electric nozzle control. There is a free circulation of chemicals with a return of spray liquid back to the tank as spraying stops. This means there is no sedimentation in the spray lines and no dead ends for spraying or cleaning, even when the boom is in vertical position. During spraying each section gets under pressure from both ends of the spray lines, so the operator can immediately start spraying without any pressure drop. It is easy for the operator to program the number and size of sections which fits the best to their requirements and field situations.

Boom Guide

Boom guide is an automatic boom height control system that helps the operator to maintain your chosen spraying height. Ultrasonic sensors control the sprayer's hydraulics to guide the boom.

Sensors with Hybrid Mode as standard

This unique sensor technology, provides excellent guidance in many different and challenging field conditions and crops. The hybrid mode not only measures the distance to the plant (upper growth), it also measures the distance to the ground or bottom parts of growth at the same time. There are three different modes:

- Soil mode: the sensors only see the bottom. The soil remains representative.

- Crop mode: the sensors only see the crop. In a closed crop the sensors continue to automatically follow the crop (top).

- Hybrid mode: the sensors see the crop and the soil. The sensors follow the soil surface and the crop. When the crop is uneven, a uniform crop is virtually determined. Used in unclosed or uneven crops.

The advantage is a perfect boom guidance at higher speed and a total respect of the optimal nozzle distance to the crop, which result in highest efficiency of the application and reducing drift to a minimum level.

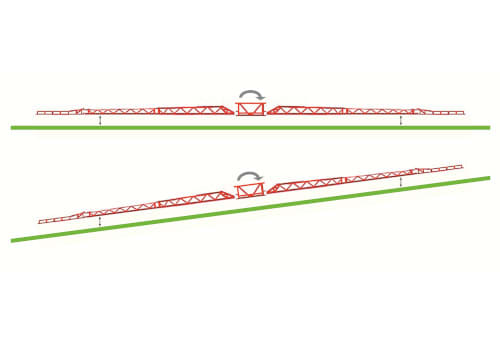

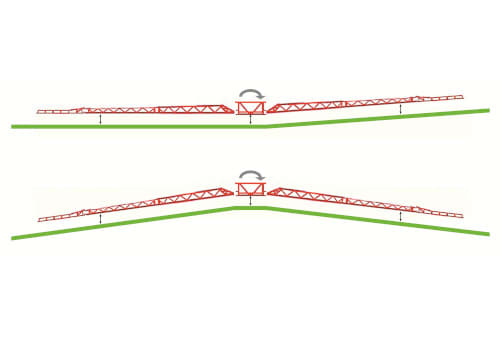

Boom Guide ComfortActive

The two ultrasonic sensors, with integrated roll sensors on the boom, can control the spray height via the central slope correction and boom lift functions. A proportional hydraulic valve is steering the central, hydraulic slope correction cylinder. The cost-effective system is suited to gentle slopes, uneven crop conditions and lower driving speeds.

Boom Guide Pro

This advanced system uses three ultrasonic sensors to control left- an right-hand boom sections independently for the ultimatic guidance in the most challenging field conditions. It can deliver positive and negative lateral movement on each side of the boom to follow the contours in every situation!

Boom Guide ProActive

The system proactively reacts on boom movement and controls both the central and independent slope correction, as well as boom lift functions to guide the boom over the crop canopy, soil surface or a combination of both modes.

Boom Guide 5 Sensor Extension

The Boom Guide 5 sensor extension provides two additional ultrasonic sensors to ensure proper height measurements with booms reduced to 24 metres.

Balancing in Flatland Conditions

An especially designed balancing system for flatland conditions is available for HSS spray booms from 32-40 metres. This system does not require any electronic boom guidance in flatland areas. The advantage is a perfect boom guidance at higher speed and a total respect of the optimal nozzle distance to the crop, which result in highest efficiency of the application and reducing drift to a minimum level.

Storage Locker

A storage locker is integrated on the left hand side behind the door allowing you to keep your safety and cleaning equipment or tools with you on the sprayer. An additional storage locker is available for the right hand side to create even more storage place.

Easy Accessible Filters

The transparant filter bowl provides direct view on the dirt degree of the suction filter without dismounting. A valve at the bottom allows emptying the filter content before removing the bowl to avoid contamination of the hands with chemicals. The self cleaning pressure filter prevents blocking via a continuous flow keeping the filter mesh clean. The undissolved particles are returned into the tank until they are completely dispersed.

Chemical Inductor

The chemical inductor is an integrated part of the tank design. It is located next to the valve panel for easy access. Equipped with a circular rinsing system and waterproof cover, it can be rinsed safely with closed cover. Big quantities of powder and difficult mixtures are injected without any problems within seconds!

Clean Water Tank

The clean water tank is equipped with a level indicator. It can be filled via the opening on the clean water tank. It contains sufficient clean water for thorough cleaning with the several iXclean functions.

Filling via the Suction hose

External aspirate water is filtered first by the filter on the hose and then by the suction filter. In parallel you can already use the chemical inductor to add and premix chemicals.

Hand Wash Tap

You can wash your hands via the hand wash tap which is centrally located on the valve panel.

External Washing

A cleaning kit with a 15 metre hose and a brush, can be connected to the pressure side of the pump. It is allowing precleaning of the sprayer in the field, using water from the clean water tank.

Dual Agitation System

The return flow agitation system keeps the mixture homogeneous during operation and can be easily switched off in case of foam risk or nearly empty tank. The powerful high pressure agitation with injector nozzles guarantees powerful mixing which can activate after filling or a long break.

Only spray when it is needed

Increase the environmental protection by only spray when it is needed with the new SpotSpray application within the iXspray software on the IsoMatch Tellus terminal in combination with the Kverneland sprayer !

Optimal Crop Protection

The SpotSpray application is based on a predefined prescription map with zero application rates. These prescription maps can be made in a similar way as the Variable Rate Application (VRA) prescription maps, in combination the SpotSpray application the sprayer shuts on and off. This is done based on the predefined sections in the control terminal and can even be done with normal section valves on the sprayer. Only designated spots are sprayed, which is particularly helpful when targeting weed spots, thistles, wet areas, non-germinated areas and areas with soil problems.

Another benefit is that based on the area of the spots in the VRA map, it is easy to see exactly how much spray liquid is required in the sprayer. Capacity is also increased as more hectares or fields can be covered with one tank of spray liquid.

With a relatively small investment in the SpotSpray license on the IsoMatch Tellus terminal, the return on investment is high, due to saving time and money. With this, spot spraying becomes accessible for all famers and contractors.

With SpotSpray costs can be saved by reducing the spray liquid to be used and preserve healthy crop from unnecessary treatment. This also means less crop damage.

The complete Kverneland HSS steel spray boom range comes as standard with 50cm nozzle spacing. Additional nozzle holders can be added to the boom now to create 25cm nozzle distance. The 25cm nozzles distance is required by legislation and confirmed as a low drift technology in a limited number of countries.

Improved crop coverage and reduced drift reduction

The 25 cm nozzle distance will improve the crop coverage and drift reduction, as it is possible to spray closer to the target area at 30cm spray height, by keeping an accurate distribution of spray liquid at the correct level with the correct droplet size.

Increase spray window

Easy switching from 50 to 25cm nozzle distance means more flexibility during spraying and it creates more time to spray in optimal conditions. In addition, the weather has less of an effect. It is easy to change from 50 to 25 cm nozzle distance or the other way around. The 25cm nozzle distance is an optional add on, on top of the standard 50cm nozzle distance for all spray line systems (central sections, iXflow-Air and iXflow-E). Even it is possible as retrofit.

iXflow-Pulse - Pulse Width Modulation system - creates the most effective agronomical spraying due to an optimal balance between droplet size, crop coverage and water use, also under changing conditions of speed or application rate.

Optimal droplet size for maximum efficiency

iXflow-Pulse is creating a flexible and fast adjustable opening and closing time of the nozzles. When driving faster the opening time will become longer. When driving slower the opening time gets shorter, but by using the iXflow-Pulse the right droplet size will be kept.

Stable spraying pressure

Precision spraying is all about the right spraying pressure in combination with the nozzle to get the right droplet size. iXflow-Pulse (Pulse Width Modulation) takes care of a stable spraying pressure over a wide speed range during variation in application rate. For example, during speed variation at start/stop on headlands, slowing down during turning or when driving and spraying up or down the hill. Another benefit is that the pressure and flow can be adjusted separately as well as during operation. One nozzle can be used for a wider range of applications, which means less changes of nozzles required, saving time and increasing efficiency. There is also the ability to use lower pressure with the same nozzle in challenging or windy conditions. iXflow-Pulse improves the coverage of the spray target in combination with a minimalisation of drift and evaporation.

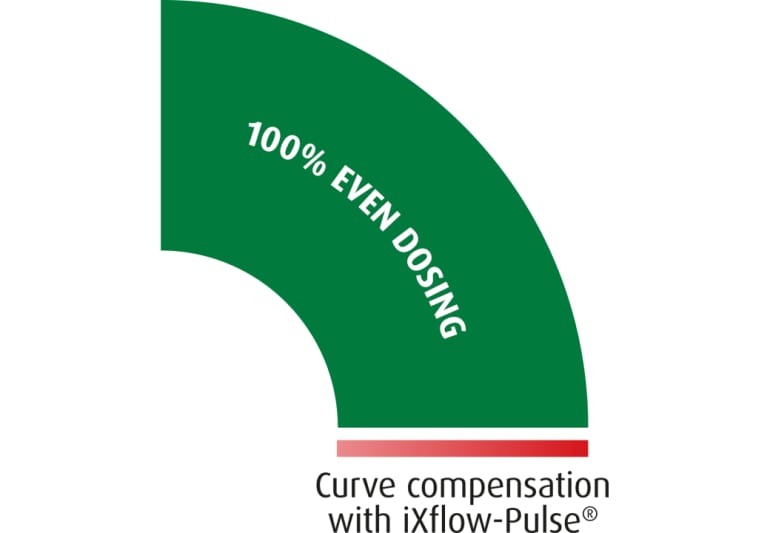

iXcurve - even dosing in curves

When spraying in different field conditions, for example driving in curves or passing obstacles, the left and right boom has a different speed and this can cause overdosing or under dosing. With the feature called iXcurve, which is included in the iXflow-Pulse system, the modulating spray pulses by adapting the opening and closing time to compensate the speed difference, resulting in an evenly covered crop or surface with the right amount of spray liquid.

The chemical inductor of the Kverneland sprayer range is adapted to integrate a Closed Transfer System (CTS) equipment directly at the filling station. A CTS is giving a safe, precise and environmental friendly solution to transfer the plant protection products to the sprayer. The goal is a spill-free filling with minimum risk for both operator and the environment by reducing point source contamination and operator exposure.

Environmental benefit

A Closed Transfer System ensures a safe, quick and precise way of filling the product in the right concentration as well as integrated cleaning of housing and container. Therefor the use of a Closed Transfer system limits the main risk of point source contamination into soil or surface water by limiting the risk of product leakage during filling operation. The complete product is used and the cans are completely emptied and cleaned by the CTS system, so only empty and clean cans are left for recycling.

Quick, safe and precise filling

With a Closed Transfer System there is no need to manually open containers and put the liquids into the open induction hopper. Alternatively, the containers are directly placed on the CTS housing to allow the products to flow in a controlled way into the sprayer, even if a container volume is only partly needed. The remaining induction bowl provides users still the possibility to safely fill products like powders and granules into the machine. The chemical inductors are equipped with a suction connection to transfer the liquid into the main tank and a pressure connection for clean water to rinse and clean the containers, interface and CTS equipment after use.

Technical specifications

Technical specifications

Download brochure| iXtrack T6 | |||

|---|---|---|---|

| Nominal tank volume (l) | 6400 | 7600 | |

| Maximum tank volume (l) | 7000 | 8300 | |

| Chemical inductor (l) | 37 | 37 | |

| Clean water tank (l) | 620 | 620 | |

| Hand wash tank (l) | 32 | 32 | |

| Spray boom (m) | HSA 21-33/HSS 27-40 | HSA 21-33/HSS 27-40 | |

| Pumps (l/min) | 200/260/400/520 | 200/260/400/520 | |

| iXclean | iXclean Comfort/iXclean Pro | iXclean Comfort/iXclean Pro | |

| Controls for ISOBUS Electronics | IsoMatch Tellus PRO/GO+ or any other ISOBUS terminal | IsoMatch Tellus PRO/GO+ or any other ISOBUS terminal | |

| Wheel axle (m) | 1.80-2.25 by changing rims | 1.80-2.25 by changing rims | |

| Drawbar | Top or hitch linkage in combination with pulling eye or ball coupling | Top or hitch linkage in combination with pulling eye or ball coupling |

Technical specifications

Technical specifications

Download brochureiXtrack T6 | |||

Tank capacity |

6400 litres |

7600 litres |

|

Spray booms |

HSA 24 - 33 m / HSS 24 - 40m, 30/24m and 36/24m |

||

Drawbar |

Hitch linkage in combination with pulling eye or ball coupling |

||

Wheel axle |

1.80 - 2.25m by changing rims |

||

Pumps |

200 - 260 - 2x 200 - 2x 260 (l/min) |

||

Clean water tank |

500 litres |

||

Regulation systems |

IsoMatch Grip in combination with IsoMatch Tellus Pro, IsoMatch Tellus GO+ or any other ISOBUS terminal |

||

iXclean |

iXclean Comfort / iXclean Pro |

||