DG II

Seeder | Pneumatic Solo Seed Drill

Effective sowing with high capacity seed drill for high and precise seed output.

High capacity trailed seed drill meets the request for utmost efficiency and output

The advantages of this Pneumatic Solo Seed Drill

- High performance and large capacity

- Active-on system for superior seed depth control

- Precise seed placement by ELDOS and CD coulter

- Good visibility and manoeuvrability

- Easy accessible for setting and maintenance

Description

The Kverneland DG II trailed seed drill combines high performance, safe, rapid transport, ease of adjustment, and short preparation times in one machine. With a working width of 9 or 12 meters and a hopper capacity of 6,000 litres, the DG II is a perfect high capacity seed drill for up to 140 ha in one day!

The narrow profile of the seed coulters with their slightly off-set steel discs allows easy penetration into the soil for most precise seed placement. With on the go adjustment of seeding depth and coulter pressure by the Active-on system (up to 80kg) and the automatic headland management, the high capacity DG II offers operator comfort and safe application. Large sized wheels (800/45 x 26.5) ensure safe handling on the road and low pressure on the soil.

Highlights

- High performance and large capacity

- Superior seed depth control also at high working speeds by Active-on system

- Strong frame design for stability and reliability

- State of the art seeding technology with ELDOS and CD coulter

- Good visibility and manoeuvrability

- Compact on the road in transport position

- Easy accessible for setting and maintenance

Features

Features

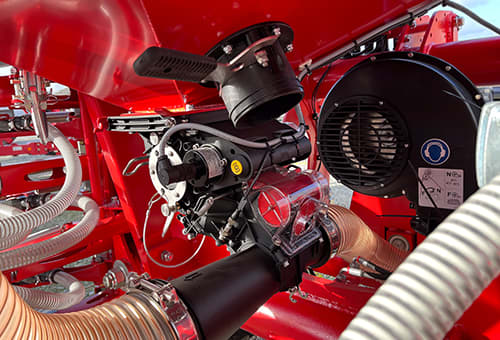

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

Due to the compact design of the Kverneland DG II, this large machine generally requires no special authorization for road transport. With a width of 3 metres and a height of 4 metres, its dimensions are within European traffic regulation standards. The machine’e dimensions also allow it to pass through standard bridges and tunnels.

The machine is connected to the tractor via the lower link hitch CAT 3*. The road lights and fixed warning signs are fitted as standard to ensure in combination with the optional dual-circuit air brakes (or hydraulic brake) compliance with traffic regulations and safe movement of the machine on roads.

The machine tows exceptionally well due to the sturdy axles and floatation wheel equipment, it can be authorized to be towed at speeds up to 40 km/h. This results in transport and machine preparation times being reduced. The seeding operation becomes faster and more efficient. The machine’s great manoeuvrability and ease of transport ensures that lower lying fields and small pockets of land can also be reached. For safe parking of the machine a sturdy parking leg is fitted.

* CAT 3, 3N and 4 N lower link hitches, and a hydraulic braking system are available as options..

In order to give sufficient support to the 6000l seed hopper and two-section coulter bar, Kverneland developed a sturdy frame design for the DG II that distributes the weight of the machine evenly between the carrier axle and the tractor.

The 800/45 x 26.5 wheel equipment ensures safe handling on the road and low pressure on the soil. In the working position the independently mounted toolbars are supported by sensor wheels that ensure accurate tracking and seed depth for the individual coulters during the seeding operation.

Powerful hydraulic cylinders guarantee safe conversion from the transport position to the working position and vice versa!

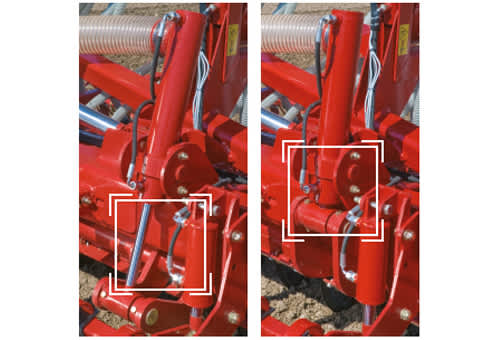

With Kverneland's Active-on system, the coulter pressure can be adjusted up to a maximum of 80 kg. The system benefits from the interaction between the coulter pressure and the pressure of the coulter toolbars across the entire width of the machine.

Where coulter pressure is high (retracted cylinder), the pressure on the coulter toolbars is increased. This in turn produces a back pressure for the coulters which results in excellent coulter penetration! With the series e-com model, the pressure can be adjusted to between 0 and 90 bar from the control unit located in the tractor cab.

The Active-on system actively regulates the coulter pressure with the help of individual pressure sensors thus guaranteeing that the pressure set is maintained in order to ensure the precision and consistency of the sowing depth. In order to reduce the load on the toolbar wheels during turning at the headland, the coulter pressure/coulter bar pressure is always neutralised and then automatically increased again to the pre-set value when the coulter bars are lowered again.

Kverneland engages in active, intelligent prevention of wear!

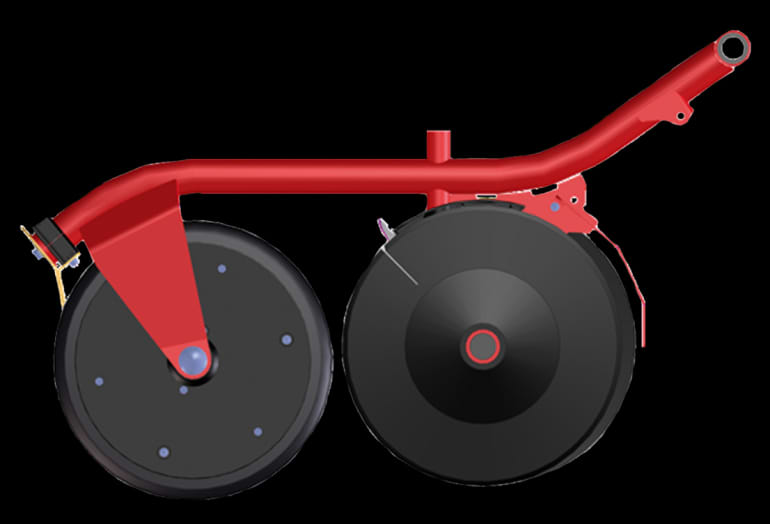

The CD mulch seed coulter consists of two steel discs (Ø410mm) with 12.5cm row spacing. Thanks to its very slim design the soil movement is very little, which leads to a smaller need for pressure to achieve the seeding depth. Thus more of the available coulter pressure of up to 80kg can be led to the press wheels when needed. The coulter pressure can be set infinitely.

Fully integrated maintenance-free disc bearings provide an easy flow of the coulter. The press wheels (Ø 380mm) are made of special rubber which has a self-cleaning effect. So in most conditions no scrapers are required.

The coulter staggering is 175mm. The coulter pressure adjustment is done centrally and can be set infinitely from 0-80kg. The seed depth adjustment is steered centrally via the ISOBUS terminal (series equipment). The two distribution heads are mounted on the coulterbar.

Advantages:

- Extremely narrow profile design – less pressure required for penetration

- Reduced pulling force – due to less soil movement

- Integrated depth guidance and press wheel functionality

- Maintenance free, high performance bearings

In order to give sufficient support to the 6000l seed hopper and two-section coulter bar, Kverneland developed a sturdy frame design for the DG II that distributes the weight of the machine evenly between the carrier axle and the tractor.

The 800/45 x 26.5 wheel equipment ensures safe handling on the road and low pressure on the soil. In the working position the independently mounted toolbars are supported by sensor wheels that ensure accurate tracking and seed depth for the individual coulters during the seeding operation.

Powerful hydraulic cylinders guarantee safe conversion from the transport position to the working position and vice versa!

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

The CD mulch seed coulter consists of two steel discs (Ø410mm) with 12.5cm row spacing. Thanks to its very slim design the soil movement is very little, which leads to a smaller need for pressure to achieve the seeding depth. Thus more of the available coulter pressure of up to 80kg can be led to the press wheels when needed. The coulter pressure can be set infinitely.

Fully integrated maintenance-free disc bearings provide an easy flow of the coulter. The press wheels (Ø 380mm) are made of special rubber which has a self-cleaning effect. So in most conditions no scrapers are required.

The coulter staggering is 175mm. The coulter pressure adjustment is done centrally and can be set infinitely from 0-80kg. The seed depth adjustment is steered centrally via the ISOBUS terminal (series equipment). The two distribution heads are mounted on the coulterbar.

Advantages:

- Extremely narrow profile design – less pressure required for penetration

- Reduced pulling force – due to less soil movement

- Integrated depth guidance and press wheel functionality

- Maintenance free, high performance bearings

With Kverneland's Active-on system, the coulter pressure can be adjusted up to a maximum of 80 kg. The system benefits from the interaction between the coulter pressure and the pressure of the coulter toolbars across the entire width of the machine.

Where coulter pressure is high (retracted cylinder), the pressure on the coulter toolbars is increased. This in turn produces a back pressure for the coulters which results in excellent coulter penetration! With the series e-com model, the pressure can be adjusted to between 0 and 90 bar from the control unit located in the tractor cab.

The Active-on system actively regulates the coulter pressure with the help of individual pressure sensors thus guaranteeing that the pressure set is maintained in order to ensure the precision and consistency of the sowing depth. In order to reduce the load on the toolbar wheels during turning at the headland, the coulter pressure/coulter bar pressure is always neutralised and then automatically increased again to the pre-set value when the coulter bars are lowered again.

Kverneland engages in active, intelligent prevention of wear!

Due to the compact design of the Kverneland DG II, this large machine generally requires no special authorization for road transport. With a width of 3 metres and a height of 4 metres, its dimensions are within European traffic regulation standards. The machine’e dimensions also allow it to pass through standard bridges and tunnels.

The machine is connected to the tractor via the lower link hitch CAT 3*. The road lights and fixed warning signs are fitted as standard to ensure in combination with the optional dual-circuit air brakes (or hydraulic brake) compliance with traffic regulations and safe movement of the machine on roads.

The machine tows exceptionally well due to the sturdy axles and floatation wheel equipment, it can be authorized to be towed at speeds up to 40 km/h. This results in transport and machine preparation times being reduced. The seeding operation becomes faster and more efficient. The machine’s great manoeuvrability and ease of transport ensures that lower lying fields and small pockets of land can also be reached. For safe parking of the machine a sturdy parking leg is fitted.

* CAT 3, 3N and 4 N lower link hitches, and a hydraulic braking system are available as options..

Technical specifications

Technical specifications

Download brochure| Model | DG II 9000 | DG II 12000 | |

|---|---|---|---|

| Working width (m) | 9.00 | 12.00 | |

| Transport width (m) | 3.00 | 3.00 | |

| Transport length (m) | 8.55 | 8.55 | |

| No. of metering devices ELDOS® | 2 | 2 | |

| Seed rate with 15km/h (kg/ha) | 1 - 320 | 1 - 320 | |

| Hopper capacity (l) | 6,000 | 6,000 | |

| Filling height (m) | 3.10 | 3.10 | |

| Required oil volume | > 110l/min | > 110l/min | |

| Single-acting hydraulic valve + zero-pressure return for fan drive | Standard | Standard | |

| 1 x double-acting hydraulic valve for machine control | Standard | Standard | |

| Power requirement 12 V > 70 A | Standard | Standard | |

| Elektro-hydraulische Einstellung der Ablagetiefe via ISOBUS Terminal | Standard | Standard | |

| No. of CD coulters | 72 | 96 | |

| Coulter pressure up to 80kg (Active-on system) | Standard | Standard | |

| Press wheels (Ø 380 x 50 mm) | Standard | Standard | |

| Scraper of press wheels | Option | Option | |

| Row spacing (12,5 cm) | Standard | Standard | |

| Electronic adjustment of the seed quantity with radar | Standard | Standard | |

| Filling level sensors in the seed hopper (no.) | Option (2) | Option (2) | |

| Hydraulic fan drive | Standard | Standard | |

| Fan speed sensor | Standard | Standard | |

| Metering device monitoring | Standard | Standard | |

| Electronic half-width shut-off | Standard | Standard | |

| Magnetic shut-off valves (max. no.) | Option (8) | Option (8) | |

| Calibration set | Standard | Standard | |

| LED working lights | Option | Option | |

| Maintenance platform, lightning for road transport and inside the hopper | Standard | Standard | |

| Lower link hitch CAT III (965mm) | Standard | Standard | |

| Lower link hitch CAT III N (825mm) | Option | Option | |

| Lower link hitchg CAT IV N (965mm) | Option | Option | |

| Hydr. clod board | Option | Option | |

| S-Following harrow 10mm | Standard | Standard | |

| Finger following harrow 12mm | Option | Option | |

| Hydraulic foldable trackmarker arms with notched discs | Option | Option | |

| Hydr. track eradicator (2 tines per tractor track) | Option | Option | |

| Track eradicator (2 tines per wheel of the wing segment) | Option | Option | |

| Track eradicator (3 tines per transport wheel DG II) | Option | Option | |

| Transport wheel (mm) | 800/45-26.5 | 800/45-26.5 | |

| Wheels of the wing segment (mm) | 31x15.5-15 | 31x15.5-15 | |

| Pneumatic brake | Option | Option | |

| Hydraulic brake | Option | Option | |

| Pre-emergence marker (centre marking) | Option | Option | |

| iM Tellus for non-ISOBUS-capable tractors | Option | Option | |

| iM Tellus for ISOBUS-capable tractors | Option | Option | |

| Headland management | Standard | Standard | |

| Max. road transport speed (km/h) | 40 | 40 | |

| Weight (kg) (Basic equipment) | 6,850 | 7,660 | |

| Min. power requirement (HP) | 180 | 230 |

Technical specifications

Technical specifications

Download brochureModel |

DG II 9000 |

DG II 12 000 |

Working Width (m) |

9.00 |

12.00 |

Transport Width (m) |

3.00 |

3.00 |

Transport Length (m) |

8.20 |

8.20 |

No. of coulters |

72 |

96 |

Row distance (cm) |

12.5 |

12.5 |