Kverneland Lynx 3000

Weeder | Guidance Interface

Kverneland Lynx 3000 the best manoeuvrability for absolute in-row accuracy

The Lynx 3000 is the heavier model (965 to 1020kg) of the Kverneland guidance interfaces and ensures the best manoeuvrability of inter-row cultivator from 6.00 to 12m working width for absolute in-row accuracy. Attachable onto any type of foldable inter-row cultivator or fully integrated version with the Onyx 4000 F models.

The advantages of this Guidance Interface

- Easy control

- Utmost accuracy

- Flexibility

- Extended range

- Reliability

- Operator-friendly

Description

The Lynx 3000 is equipped with an HD colour-scanning camera, which allows self-steering following in-row crops and distinguishes plants from weeds based on different shades of green or the RGB colour profile even in higher growth level of the crop. The in-cab display can handle one or two cameras, depending on the option. The track width fits exactly to the tractor’s track, to the millimetre, suitable with special tractors.

Highlights

- HD colour-scanning analysis camera. 2nd camera as option for even more precision

- Easily adapted to different track widths (1.6m - 1.7m - 1.8m - 1.9m - 2m)

- Large diameter of the anchor wheels (550x180mm)

- Large lateral fast and smooth side-move of 25cm on both sides

- Cat.III on the tractor side / Cat.II on the inter-row cultivator side

Features

Features

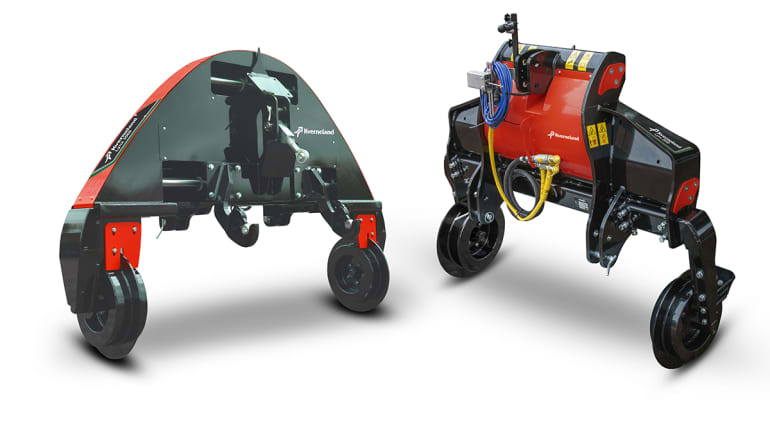

Kverneland guidance interface available in two models: Lynx 2000 and Lynx 3000 suitable for various tractors and implements.

There is also the option of a fully integrated version with the guidance interface Lynx 3000 and the inter-row cultivator Onyx 4000 F. The choice of the right model depends on the weight of the tractor and the inter-row cultivator, the required lifting capacity and also the geographic conditions in the field.

The LYNX guidance interface features a top-of-the-technology colour scanner camera allowing mechanical weeding also in higher vegetation. Here special row sensors/feelers support the steering of the Lynx.

One camera is standard and a second optional. The camera features Tillet & Hague technology, has a 6mm waterproof lens, HD-vision and enables 30 frames per second. It managed high-crop operation, recognises shadow effects and strong light intensity. This prevents damage to crops during weeding. A second camera compensates for signal losses at headlands, gelled plots and places where the crop has not emerged. This achieves an even more accurate hoeing image.

When weeding in developped crop and the leaves cover the entire surface, the feeler sensor kit follows the row crop and takes control.

The LED working lights allow working at night and may also compensate the shadow effects.

The large-dimensioned anchoring wheels of the Lynx add extra stability to the inter-row cultivator thus increasing precision and in-row accuracy. This is especially important when working in hilly conditions or with wider working widths.

- Large diameters

- Lynx 2000: 480mm x 150mm

- Lynx 3000: 550mm x 180mm

- Scrapers as standard

- Track width adjustment

- Lynx 2000: from 1.50m to 2.30m

- Lynx 3000: from 1.50m to 2.00m

Technical specifications

Technical specifications

Download brochureModel |

Lynx 2000 |

Lynx 3000 |

Linkage Tractor - Lynx |

Cat. II |

Cat. III |

Linkage Lynx - Onyx |

Cat. II |

Cat. II |

Linkage- Lifting (kg) |

1600 |

2800 |

Weight (kg) |

550 |

965 to 1020 |

Track width (m) |

1.50 to 2.30 |

1.50 to 2.00 |

Lateral range (mm) |

500 (2x250) |

500 (2x250) |

Anchor wheel (mm) |

480x150 |

550x180 |

Height adjustment (m) |

0.60 to 0.68 |

- |

Oil requirement (l/min) |

18 |

18 |

Camera |

1 x standard / 2nd optional |

1 x standard / 2nd optional |

Feelers kit |

option |

option |

LED working light |

option |

option |

Console |

9" |

9" |