TrailedLine Classic Duo

Hopper capacities from 12m³ to 25m³

Description

The Kverneland Siloking Classic Duo with 2 turbo augers addresses the workload of larger farms and farms with narrow and low barn passages.

With its 2 high-performance turbo augers, the Classic Duo offers enormous capacities, also with longer transport distances and big herds. The 2-speed gearbox as standard equipment and the appropriate hopper geometry offer smooth operation and optimal mixing results.

The low 'T' mixers (14 m³ and 18 m³) are particularly suitable for farms with low barn passages due to their low loading height.

Features

Features

- The Turbo Auger height is adjusted to the hopper height providing perfect auger-hopper ratio for accurate and quick mix.

- Turbo Auger with slow revolutions provide a gentle mix with very low power consumption.

- Adjustable Turbo Auger speed.

- The conical hopper shape optimizes feed flow back from top to hopper bottom, providing fast processing and reduced power consumption.

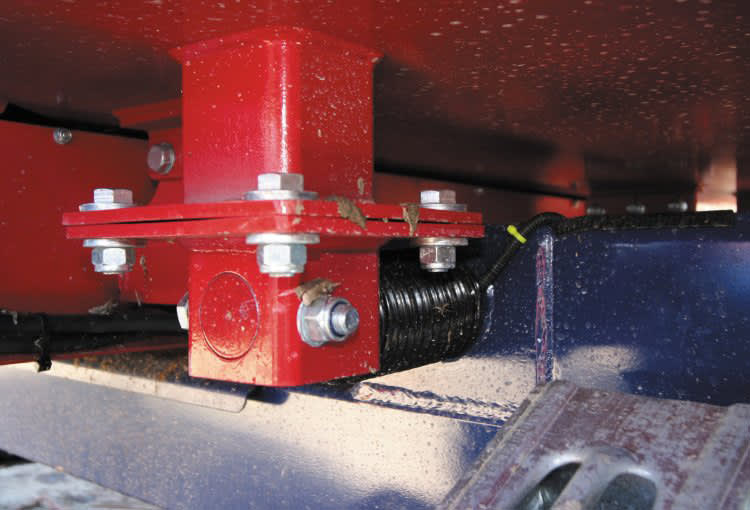

- Robust load cells ensure accurate weighing - only what is in the mixing hopper is weighed.

- Multiple adjustable hard-coated XS knives.

- For longer durability Siloking Kverneland has developed SILONOX lining as an option for the mixing augers and hopper walls, where most wearing occurs.

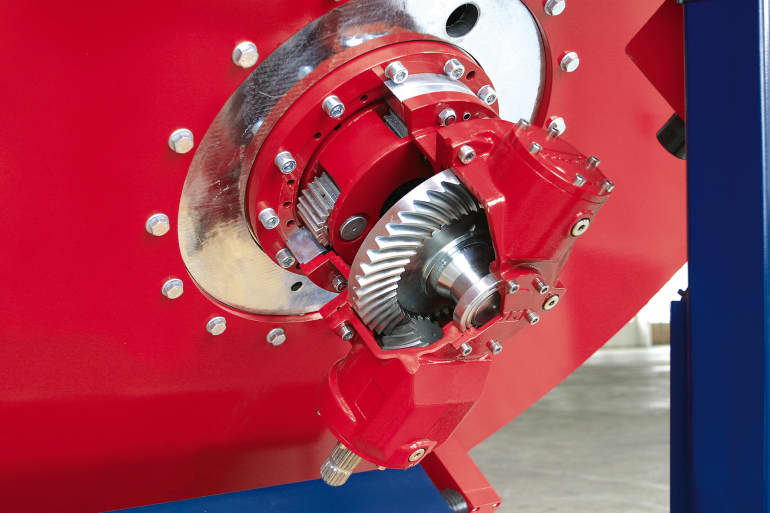

- Standard with planetary gearbox with helical bevel gear drive, the heavy duty transmission is designed for efficiency and durability, even when operating at full load.

- The relationship between gearbox and auger is carefully balanced for the optimum mixing result – high mix quality in the shortest possible time.

- All elements of the transmission – auger connection, planetary gearbox, 2-speed gearbox & drive-line – match the requirements of excellent mix results with minimum down-time.

- Precise control of ration components is needed when preparing feed rations.

- Siloking Kverneland vertical mixers are fitted with a highly accurate weighing system as standard.

- This means that exact quantities of materials can be loaded - essential for the preparation of accurate feed rations.

- Featuring multiple weigh bars mounted between hopper and separate chassis, this quality system offers very accurate control of even small components during the loading of the machine.

- Clearly visible some distance from the machine, the simple scale is standard with a fully programmable system as an option.

- The vertical mixer range can be adapted to suit a wide variety of barns or feed troughs.

- From feeding onto the floor or over high feed barriers, there is a discharge solution available.

- If needed a conveyor option can be fitted to transport material away from the door.

- Simple discharge doors - single or multiple per machine.

- Cross conveyor for discharge to either side of the machine - can be positioned at the front or rear of the machine.

- Hydraulically driven conveyors, fitted onto cross conveyor or direct onto discharge door, suitable for transporting material or into troughs.

- TwinLift conveyor - available for Compact 10-14 and Duo 14T-26. Can disharge in any position.

- The straw blower option is available on models Compact 10-T–14m³, Duo 16-18m³, Duo Avant 14-20 and Duo New Generation.

- The straw blower option offers a precise discharge of the straw inside the animal buildings.

- The 1.55m diameter front mounted flywheel comes from the Kverneland 850 series Bale Choppers – known for its´ robust design and quality distribution of straw.

- This system is mechanically driven from the tractor and located direct on the front of the machine, without the need for feed drums or conveyors.

- Drive to the flywheel is independent of the drive to the augers, supporting each phase of the process – loading, cutting, mixing and discharge.

- Straw is distributed by the side chute, offering straw blow up to 20m

- Standard with heavy-duty planetary gear drive to auger and 2-speed gearbox, allowing accurate control of auger speed during cutting, mixing and feed-out.

- 2-speed gearbox can be changed manually or via hydraulic control (option).

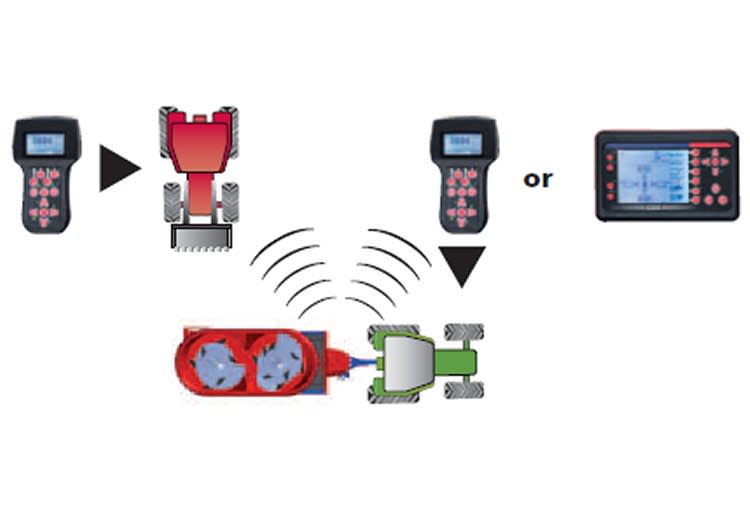

- All information available at a glance.

- Weighing system controlled from the tractor cabin.

- Wireless - no disturbance of hydraulic functions.

- All information is stored centrally in the machine box.

- Weight information is always available - even in the silo.

- Control your weighing system from the loading vehicle.

- Feeding Management Software gives you full control over loading precision and feed consumption.

- The SWT package includes adding weighing system.

- The SWE Package combines programmable weighing system with electro-hydraulic control.

Technical specifications

Technical specifications

Download brochureModel |

Capacity (m³) |

Length (m) |

Width (m) |

Height (m) |

Duo 12 |

12 |

6.00 |

1.96 |

2.62 |

Duo 13 |

13 |

6.20 |

2.06 |

2.64 |

Duo 14 |

14 |

6.35 |

2.06 |

2.76 |

Duo 14-T |

14 |

6.55 |

2.26 |

2.45 |

Duo 16 |

16 |

6.55 |

2.26 |

2.70 |

Duo 18 |

18 |

6.60 |

2.26 |

2.90 |

Duo 18-T |

18 |

6.85 |

2.42 |

2.58 |

Duo 20 |

20 |

6.90 |

2.42 |

2.87 |

Duo 22 |

22 |

6.94 |

2.42 |

3.02 |

Duo 25 |

25 |

7.35 |

2.55 |

3.22 |