TrailedLine 4.0 Premium

Hopper capacities from 14 m³ to 30 m³ with 2 mixing augers

Description

The Kverneland Siloking TrailedLine 4.0 Premium range convinces with short mixing times and homogeneous mixing results thanks to the edged hopper shape. All models are equipped with SILONOX wear protection in the area of the wedge-shaped hopper recesses and of the discharge door. The robust and torsion-free square-bar frame together with the powerful 4-planet gearbox ensures high operational reliability.

Choosing from different hopper heights and tires makes it possible to adapt the machine to the passage heights in the barn or to the maximum height of the loading vehicle. When reducing the hopper height, it is however important to adapt also the turbo auger in order to meet the quality requirements of the hopper geometry. Models from TrailedLine 4.0 Premium 3022-26 upwards are equipped with a tandem axle (with steering axle or steering axle with positive steering as option).

Features

Features

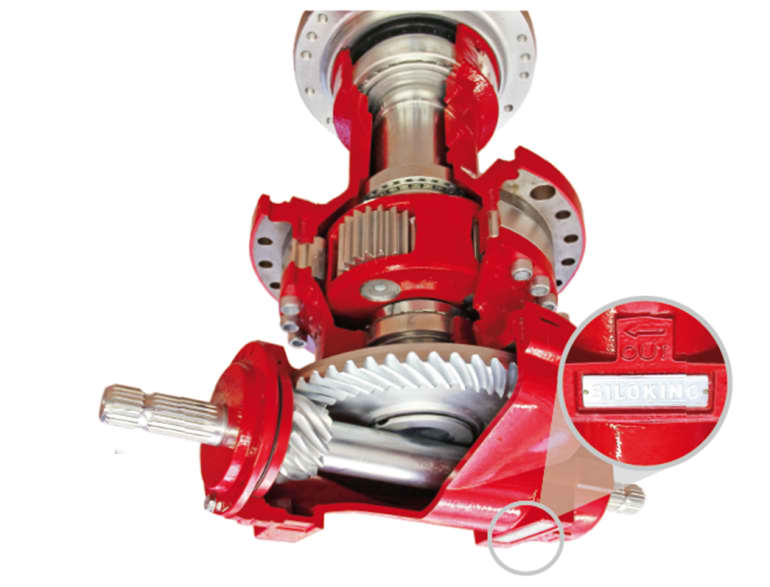

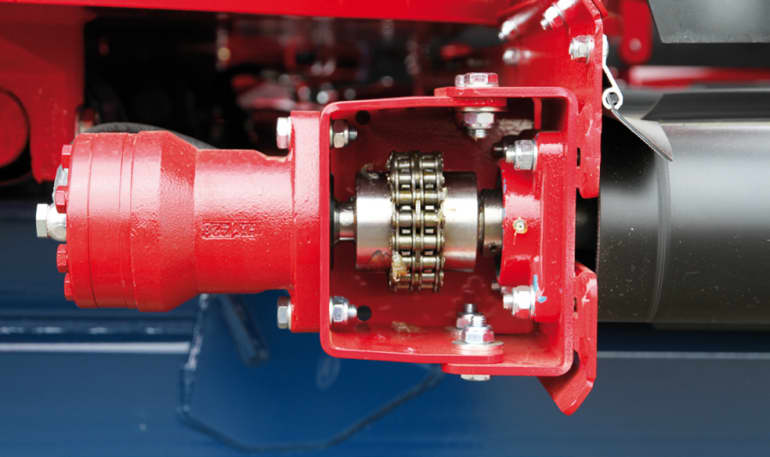

4-Planet Gearbox

- The planetary gearbox has been developed exclusively and only for use in Siloking feed mixers.

- It has been designed for efficiency and long service life even with peak loads with a maximum torque

of 52.000 Nm / 250 hp. - The gearboxes are 100 % oil-lubricated, which equates to very easy maintenance. The gearbox oil can be changed and filled up quickly and without any special tools via the big and transparent oil expansion reservoir.

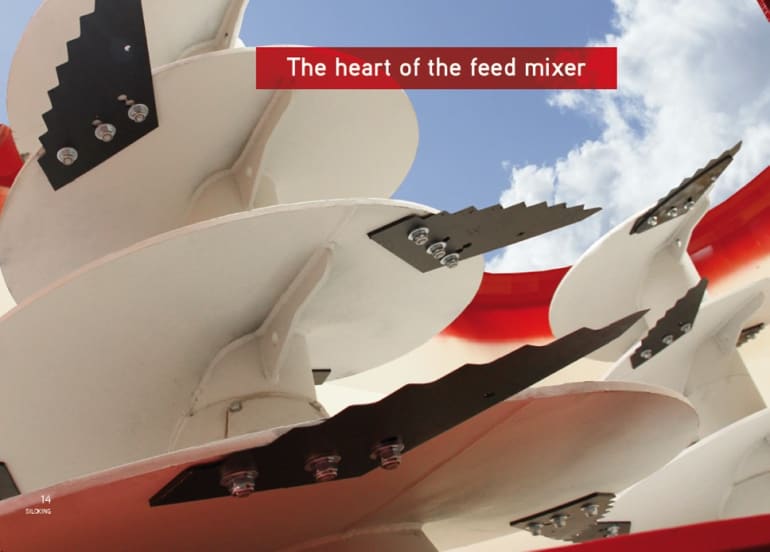

Edged Hopper

- The edged shape of the hopper slows down the feed in its circular movement and supports vertical mixing. This reduces the mixing time and preserves the feed structure at the same time.

- The edged shape increases the hopper‘s stability and avoids overflow of the mixing hopper by optimizing the flow of the feed.

- The rounded FlowPlus hopper ring takes the feed from the top back down into the mixing process, thus ensuring clog-free working, even when processing round bales. This is standard on all Siloking 4.0

models with 2 or 3 mixing augers.

The perfect ratio between the hopper height and width and the appropriate mixing auger is at the beginning of the proper operation of the mixing unit.

The hopper geometry and the turbo auger are aligned perfectly, which provides short mixing times while preserving the feed structure in an optimal way. The optimal ratio of hopper to auger reduces the power requirement considerably.

The mixing unit inside is designed so that even round bales are broken up quickly and reliably. The design ensures complete emptying and therefore avoids clogging.

A big auger with low speed preserves the structure and reduces wear. The shape of the turbo auger is the result of years of experience and extensive testing.

It rotates at a speed that can be described as gentled despite moving a high quantity of feed inside the mix with every rotation.

Every turbo auger is equipped with a turbo flight as standard. It offers shorter mixing times and quick and regular emptying. In order to offer the cow safe and clean feed, a heavy-duty neodymium magnet can be mounted as an option. It removes any metallic foreign materials from the feed.

The flat and adjustable scraping bars made of SILONOX collect even concentrates from the hopper bottom and immediately include them into the mix, which makes it possible to add fine feed components any time.

- SILONOX is a particularly hard-wearing solid stainless steel alloy with outstanding wear resistance. It is used exclusively for Siloking feed mixing technology.

- SILONOX is highly resistant to corrosion, acid and chemical degradation. It also shows excellent resistance to mechanical wear resulting from the mixing process.

- Strong welds ensure permanent tightness and secure joins – no acid can penetrate.

- Durability factor >3 compared with steel S 355 (St-52)

- Wear-resistant steel, corrosion-resistant, acid-resistant, abrasion-resistant

- Those components that are subject to the highest degrees of frictional load are provided with wear-resistant plates made of SILONOX as standard. The wedge-shaped hopper recesses between the mixing augers as well as the areas on the sides of the discharge openings are provided with SILONOX Wear protection.

- The SILONOX Wear protection consists of a special stainless steel alloy that is extremely resistant to corrosion, acids and abrasions. It minimizes wear even with high throughput quantities. This allows for the service life of the machine to be greatly expanded without requiring any retrofits.

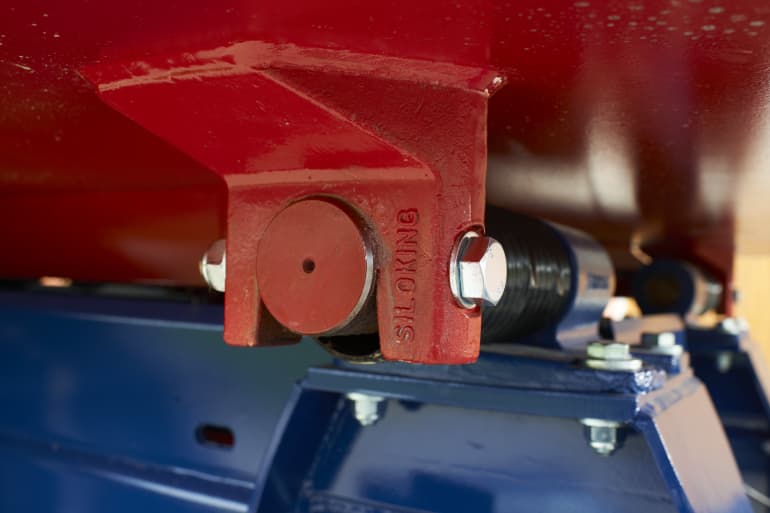

- The unique square-bar frame offers high stability and forms the basis for the torsion-resistant load cell casings.

- Together with the special load cell casings, this offers perfect weighing accuracy, even on unlevel ground and when the mixing hopper is fully loaded.

- The cables of the weighing system are acid-resistant and they run tidily and safely in cable channels. A quality feature for long life and consistently reliable operation of the machine.

- A wide frame forms the basis for better driving stability, increased transport safety and exact weighing 365 days a year.

- On the side of the hopper, the load cells are in a specially developed cast casing so that the weight transfer is carried out at one point only. The distortion-free position of the load cells on the frame ensures maximum weighing accuracy.

- A cross conveyor belt allows for depositing feed in a regular and wide feed swath, satisfying the cow‘s longing for loose feed presentation.

- Feed to be pushed in later remains fresh and the feed intake of the cows increases.

- It is a unique, reliable and long-life PVC cross conveyor belt.

- The conveying slats of different heights offer high conveying performance.

- The belt produces a wide feed swath, is highly reliable and ensures clog-free transport.

- As the slats are divided in the middle, the belt remains flexible even with different loads and is therefore reliable and low-wearing.

- A tracking rib welded inside ensures that the belt runs completely straight.

- Two drive motors located on the sides always drive the conveyor belt in the pulling direction, no matter which side discharge is carried out. Together with the cleaners inside, this design reduces wear to a minimum.

- The use of closed drive rollers, scrapers and a special discharge scraper ensures highest operational reliability.

- The chain coupling ensures power transmission from the hydraulic motor to the drive roller. It is designed for high torque load.

- The conveyor belt is 800 mm wide and open on top, for quick transport of the feed. This guarantees clog-free and gentle feed discharge.

Foldable conveyor belts on the discharge door

- They reach under the hopper on the Premium models, thus ensuring transport of feed without spillage. Available in various lengths.

Foldable conveyor belts on the cross conveyor belt

For versatile and flexible use of the feed mixer. Available in different lengths.

Heavy-duty discharge door with discharge chute

- Equipped with two lift cylinders and an opening height of 85 cm, the mixing hopper can be emptied in a very short time, even with a high proportion of structure-rich components.

Discharge door

- The sharp SILONOX edge on the hopper bottom ensures that the discharge door closes tightly even if there is still feed in the mixing hopper.

The perfect solution for any farm or installation

- Individual adaption to any situations. For example a machine with a cross conveyor belt at front and two discharge doors at rear left and at rear right, displaced to the centre by ca. 400 mm.

No interfering edge inside the mixing hopper

- SILONOX mounted on the sides of the door opening closes flush with the discharge door on the hopper inside. Robust door guide even for extreme load and highly reliable function as there is no jamming while closing.

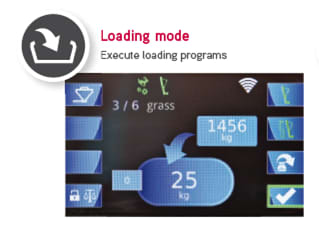

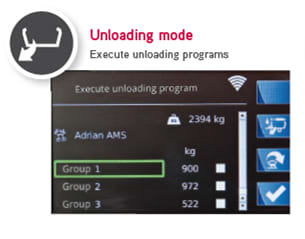

- SILOKING Data is a radio-controlled weighing system for daily use in cattle feeding. It stands out for simple and comfortable control and allows for precise feeding, efficient work and cost saving from the very beginning.

SILOKING Data T (Tractor control)

- Data radio terminal as option

- Programmable weighing system can also be used as adding weighing system

- Control of the weighing system from the loading vehicle via additional Data radio terminal and/or own smartphone or tablet is possible

SILOKING Data E (Electro-hydraulic)

- 1 Data radio terminal as standard

- Control of hydraulic functions via Data radio terminal

- Programmable weighing system can also be used as adding weighing system

- Control of the weighing system from the loading vehicle via additional Data radio terminal and/or own smartphone or tablet is possible

Feeding Management Software

- SILOKING offers the Feeding Management Software as a free top service for the SILOKING Data Programmable weighing system. This makes it possible for every farmer to work in an even more efficient and cost-saving way, regardless of farm size.

- Ration handling: create recipes, create feed components, create animal groups and unloading points, nominal/actual comparison, adaption of dry matter

- Documentation/Evaluation: storing of feeding data, evaluation for dairies, documentation for authorities & QA programs, Period-related reports (feed consumption, feed costs, loading precision)

- Simple registration via SILOKING website: www.siloking.com

- Web-based application with personalised user access

- Access from any PC via Internet browser. Offers flexible access from the office, the barn, from home or from holiday location etc.

- Thanks to the web-based application there is no need for manual updates so you are always working with the latest software version

- GPRS data transfer between weighing system and Feeding Management Software (option)

Straw blower

- High-capacity straw blower with mechanical drive

- The combination of mixing unit and straw blower allows for multiple use of the feed mixer.

- The high-capacity straw blower distributes even long-fibred material exactly and to distant places in the barn.

- The integrated stone trap between the mixing hopper and the blower avoids stone chipping in the barn.

Bedding belt

- Combination of feed discharge and large-distance bedding

- The bedding belt offers the perfect combination for feed discharge and large-distance bedding of cubicle beds and cubicle housings.

- Control of the bedding belt is carried out hydraulically, but it can also be carried out (electro-hydraulically) via Siloking Data E as an option.

- As the bedding belt is swung under the cross conveyor belt, the vehicle width is not changed.

TwinLift

- Sliding cross conveyor belt with automatic height adjustment

- This conveyor belt can be slid hydraulically to either side, and the outer end is lifted automatically by up to 50cm.

- It is also possible to slide the belt horizontally via simple lever operation.

- This system is characterized by two-sided feed discharge into high troughs.

Hybrid conveyor belt

- Diagonal conveyor belt for particularly narrow barns with high troughs

- The diagonal conveyor belt is mounted in an inclined position.

- Not foldable, it keeps the whole machine narrow, even in working position.

- The hybrid conveyor belt also offers the required collision safety as the conveyor belt protrudes only slightly beyond the right feed mixer side.

Kverneland Siloking offers a whole range of additional equipment to meet any special requirements of the respective farm.

Reliable function and correct adaption to the machine ensure reliability and comfortable work 365 days a year.

Adding weighing system

- The adding weighing system is a basic equipment for the weighing function (optional for TrailedLine 4.0 models), which exactly displays the current weight during loading and unloading.

- As opposed to Siloking Data, this weighing system is mounted on the feed mixer.

Programmable weighing system DG600

- This is available as an option for TrailedLine 4.0 models. With the program function, the maximum performance of the herd can be reached through feeding.

Other options

- Reversing camera including high-resolution monitor

- Control unit with Bowden cable control

- Wide-angle drive shaft and lower linkage

- Hyraulic shift for 2-speed gearbox

- Infinitely variable control of conveyor belt speed

- Mechanical control unit with lever operation

- On-board power supply for the weighing system

- Mineral feed filling funnel

- Several tyre options to adapt the total height

- Heavy-duty magnet on the turbo auger

- SILONOX Wear protection

- Various discharge options

- Special hopper dimensions for adaption to barn passages

- Hydraulic counter-blades

- Hydraulic jack

- and lots of other options

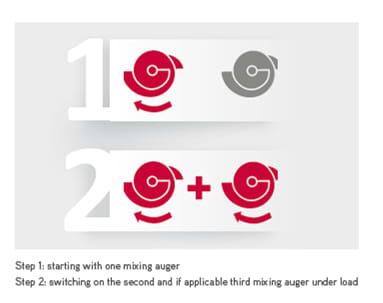

- For everyone who drives long distances or leaves the machine loaded

- During longer driving distances between silo and barn or if a high-capacity vertical feed mixer is not immediately unloaded, the material inside the hopper compacts. This results in a high starting torque requirement when starting the 2 to 3 mixing augers simultaneously, which highly strains the tractor’s PTO clutch. Furthermore a tractor with a rather high engine power is required for the start.

- Drive requirement reduced by 50 - 66 %

- SoftStart clutch as an option for the model ranges of TrailedLine 4.0 Premium, Duo Avant and System 1000+.

- This hydraulic clutch is located between the planetary gearboxes of the individual mixing augers.

- By starting only one auger – switching on the other auger(s) later – the drive requirement of the tractor can be reduced by up to 50 % (for models with 3 augers by up to 66 %).

Technical specifications

Technical specifications

Download brochureModel |

Capacity (m³) |

Length (m) |

Width (m) |

Height (m) |

Premium 1814-14 |

14 |

6.65 |

2.33 |

2.72 |

Premium 1814-16 |

16 |

6.65 |

2.33 |

2.87 |

Premium 1814-18 |

18 |

6.65 |

2.33 |

3.02 |

Premium 2218-18 |

18 |

7.10 |

2.53 |

2.73 |

Premium 2218-20 |

20 |

7.10 |

2.53 |

2.90 |

Premium 2218-22 |

22 |

7.10 |

2.53 |

3.07 |

Premium 3022-22 |

22 |

7.45 |

2.71 |

2.82 |

Premium 3022-26 |

26 |

7.45 |

2.71 |

3.23 |

Premium 3022-30 |

30 |

7.45 |

2.71 |

3.52 |