The challenges in sustainable agriculture are becoming ever greater. And when times get tough, there’s only one thing for it: innovative thinking. For example, considering how to achieve the same or even higher yield with lower input.

PUDAMA, developed by Kverneland Group Soest GmbH in cooperation with the University of Applied Sciences Cologne, has now been shown to the press and public in real operation in field.

Growing less into more

PUDAMA stands for a systematic focused spot fertiliser application during maize sowing. It enables the precise sowing of maize with the specific placement of a starter fertiliser deposit exactly below the maize seed where it is needed.

The PUDAMA advantage of a targeted, discontinuous fertiliser placement in the area of the deposited maize seeds compared to the established row fertiliser spreader is a much more favourable nutrient utilisation by the plant roots. This reduces the amount of available starter fertiliser between maize rows and significantly reduces nitrate and phosphate discharge into water systems. Based on the research conducted by Dr. Max Bouten, whilst working at the University of Applied Sciences Cologne, it could be proven that at least 25 % of the starter fertiliser can be saved with PUDAMA compared to conventional maize growing and at the same time, the yield potential is maintained. PUDAMA uses resources more efficiently and contributes to a more sustainable production of plant-based food and the protection of soil, water and air.

The PUDAMA principle

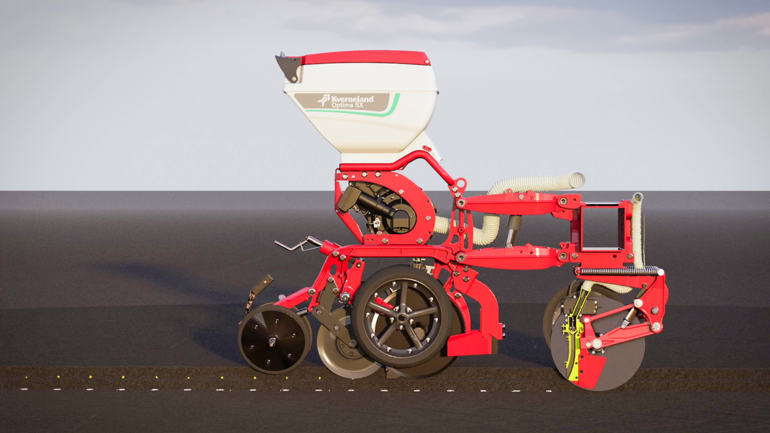

At the fertiliser coulter, the fertiliser enters the channel continuously via the metering unit and remains on a small brush in the tube. A permanent high-pressure airflow is connected to the valve via a small hose. This valve opens periodically, depending on the signals of the opto-electronics control system underneath the seeding heart. The interruption of the airflow is controlled by the valve at periodic intervals. When the airflow is stopped, the fertiliser remains on the brush. When the airflow starts again, the fertiliser is shot into the soil. As the fertiliser collects on the brush, it is shot into the soil as a deposit. How often this valve opens and closes depends e.g. on the driving speed of the tractor and the seed distance in the furrow. A working speed of up to 15kph with the Optima SX PUDAMA means a frequency of up to 25 fertiliser spots per second.

High savings

With technology such as the Optima TFprofi SX PUDAMA precision drill, farmers can save a lot of money by reducing fertiliser, transport and work costs. For example, if a farmer with 300ha of maize uses 150kg/ha DAP 18-46 in the conventional way, he would save 37.5kg/ha of fertiliser with the PUDAMA system. This means in money a saving of 7,875€ for 300ha (source: index mundi: Price DAP 700€/t Oct. 2021).

In Germany up to 81,000 tonnes of fertiliser could be saved annually in future with the PUDAMA system, which would mean that 16,200 tonnes less of pure nitrogen and phosphate would be used. This corresponds to a saving of 25 % of the fertiliser currently used annually at the same high yield level.

Saving fertiliser protects the environment by reducing resource use, including energy for fertiliser production, while reducing farm production costs and securing food production.

In acknowledgment of this innovation, PUDAMA was awarded the NRW Efficiency Award 2021 for resource-saving product development, environmentally friendly manufacture and reduced environmental impact during the product's life, as well as comprehensive recyclability.

The Kverneland Optima TFprofi SX with PUDAMA configuration will be available for season 2023 as limited edition; it will be fully available for season 2024.

The PUDAMA system will also be available for other Optima models in future.