Kverneland is known worldwide for high ploughing performance. The long experience dating back to 1879 and the constant care for the best ploughing results have shaped a comprehensive range of Kverneland bodies adapted to any soil conditions and tractor tyres. Kverneland Body 38 is designed as “the all rounder”.

A versatile plough body

Soil structures and conditions are often different field to field, season to season, sometimes even within the same field. Crops are rotated and require a different ploughing. With Kverneland Body 38, adapt the ploughing depth to any soils and plant residues for the best burial whenever. This creates the best environment for plant growth by placing the organic materials in your desired horizon.

Body 38 offers the possibility to plough from deep to shallow with the same plough. In addition, adapting the ploughing depth year to year favors a good soil structure, by avoiding the creation of pans for example (the pan can also be prevented by using the Kverneland Eco-share). Hence soils are taken care of.

Kverneland Body 38 is designed for high ploughing performance from 12-35 cm deep.

Adapted to modern farming

Professional farming requires the correct equipment. Tractors are bigger and tyres get larger. Many use 710mm tyre types. A wide empty furrow is hence required. The long Body 38 creates the necessary empty furrow to ensure the correct burial of residues.

Kverneland Body No 38

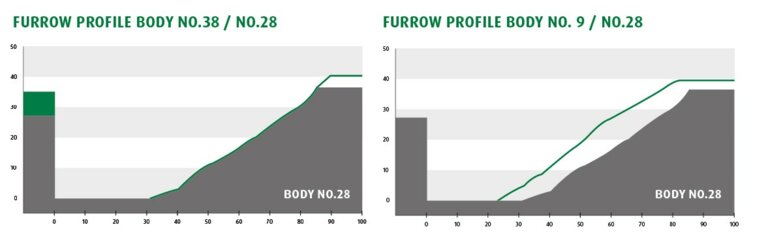

Kverneland Body 38 combines some performance from the existing bodies 28 and 9. Body 9 already enabled ploughing down to 35 cm but Body 38 creates a large empty furrow, ideal for wide tyres.

Body 38 features the same shape as the popular Body 28 specifically designed for tractors with large tyres. Body 38 enables a deeper ploughing than body 28. Not least, the same high ploughing performance are achieved for bodies 28 and 38 when ploughing shallow.

Efficient turning

The variety of soil conditions and crops may motivate the change of body types for the best burial results; but in most cases, a universal body is actually chosen. Body 28 is a universal body. Its ploughing performance have convinced most Kverneland ploughmen to chose it. Per Arne Salvesen, senior Product Application Specialist at Kverneland Klepp (Norway) reminds us that “Kverneland being the no 1 plough producer in Europe, body 28 being fitted to most Kverneland ploughs, it is hence the most sold body in Europe.”

Designed after the successful body 28, body 38 is ideal for large tractor tyres and offers the possibility of ploughing deeper.

To prepare land ahead of sugar beet and potatoes, “although we have the option of ploughing on-land, there are times when conditions dictate running in-furrow for better traction, and wide tyres would impact on the front furrow,” “and these bigger mouldboards”, ie body 38, “solved the problem immediately. The quality of our ploughing is once again, top-notch,” says Bob working with his brother Philip, family business of 1980 acres, North Walsham-based FJ Clabon and Partners at Rookery Farm, UK.

Kverneland Body 38 offers the best results in medium to heavy soils. In the latter, the soil is firmly packed with all stubble and weeds buried for a rapid residues breakdown.

Body 38, Rookery Farm, UK.

Economical

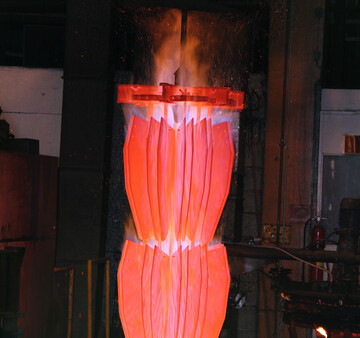

Having an “all-rounder” body is obviously economical. In addition, body 38 benefits from the same Kverneland steel technology as any Kverneland bodies to guarantee its low wear: 12 hours carburising processes creating an outer layer as hard as diamond from a specific Kverneland steel. Low wear induces cost savings and less downtime. Attention to details is also important. Kverneland bodies are low draft-low fuel consumption thanks to their design. Kverneland bodies are grinded to offer a uniform surface for an even furrow and to optimise soil flow.

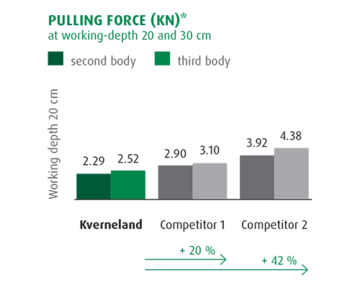

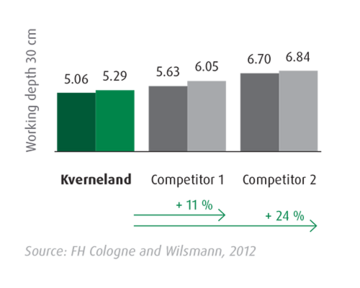

The Cologne University of Applied Sciences (2014) and Wilmsmann (University of Hohenheim, 2013) have compared the pulling forces of a Kverneland plough with its equivalent from 2 other brands. The pulling force measurements at 20 cm and 30 cm depth on the 2nd and 3rd bodies indicate clear results: the Kverneland plough offers the lowest pulling forces regardless the working depth.

BA Thesis: Comparison of different plough bodies as regards to pulling requirements and working performance.

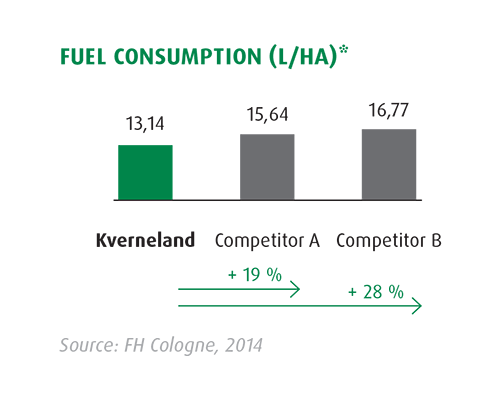

The 2014 study by the Cologne University of Applied Sciences shows that the Kverneland plough needs from 19% up to 28% less fuel than competitors. Kverneland body 28 and equivalent bodies from competition had been chosen.

Body 38 follows the same logic as being a slightly bigger copy of the No 28. By ploughing deeper, the pulling forces would be higher than by ploughing shallow but they would remain lesser than competition. Less draft, less fuel consumption, more economical.

Deep ploughing benefits

If shallow ploughing is popular, ploughing deep is an efficient mechanical means (conv. to a chemical process) to control weeds like Creeping Thistle (Cirsium Arvense). It also buries efficiently the long residues, deep roots of winter cover crops and maximises extra organic matter.

Kverneland keeps on innovating for the farming community benefits with Body No 38, “The all rounder”.