Some soil structures require a seedbed preparation with a minimum disturbance. Several techniques are available, but the compliance with the “Green Deal” aiming at reducing chemical usage and the necessity to control weeds, slugs and pest mechanically challenge farmers. The Kverneland Ecomat On-land shallow plough offers an environment-friendly efficient solution while limiting the risk of soil compaction by ploughing On-land. High profitability and extra safety during transport are not least.

Efficient shallow ploughing

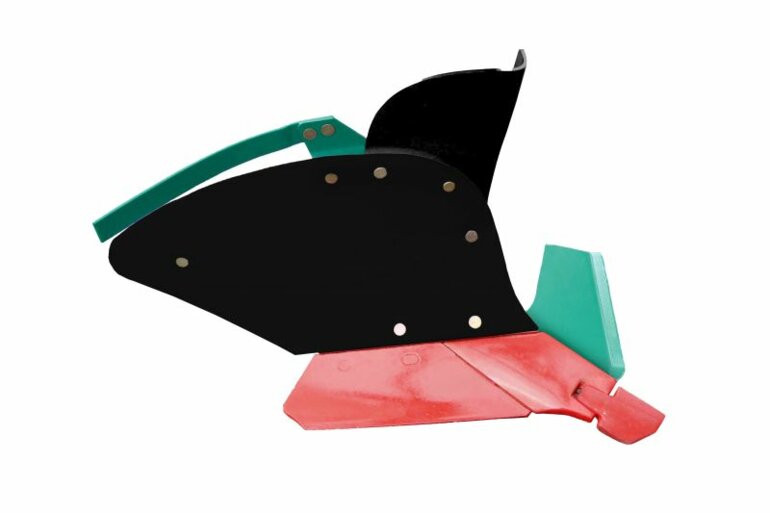

Kverneland bodies are famous worldwide for their high ploughing performance. The Kverneland Ecomat On-land benefits from the best elements of the existing Kverneland Ecomat (in-furrow version): the Ecomat bodies.

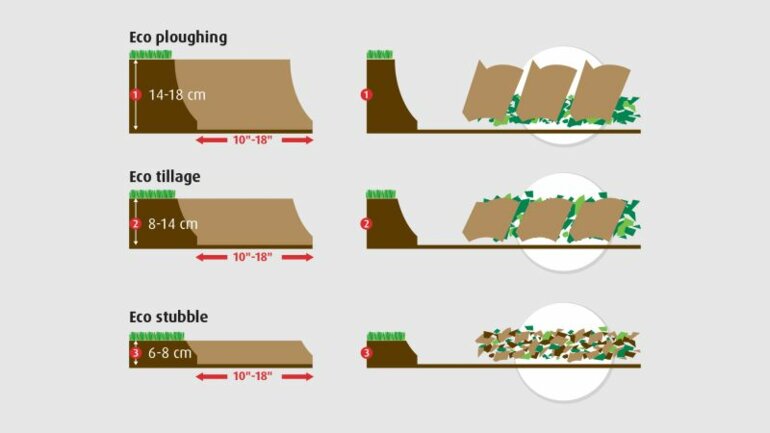

Their special design: short, high and very cylindrical, enables a 180° efficient soil turning effect. Fitted with a specific range of accessories, the steel or plastic Ecomat bodies can be flexibly used in different soil structures, residues and adjusted to the desired working depth from 6-18 cm.

The beam located in the middle of the body prevents blockages.

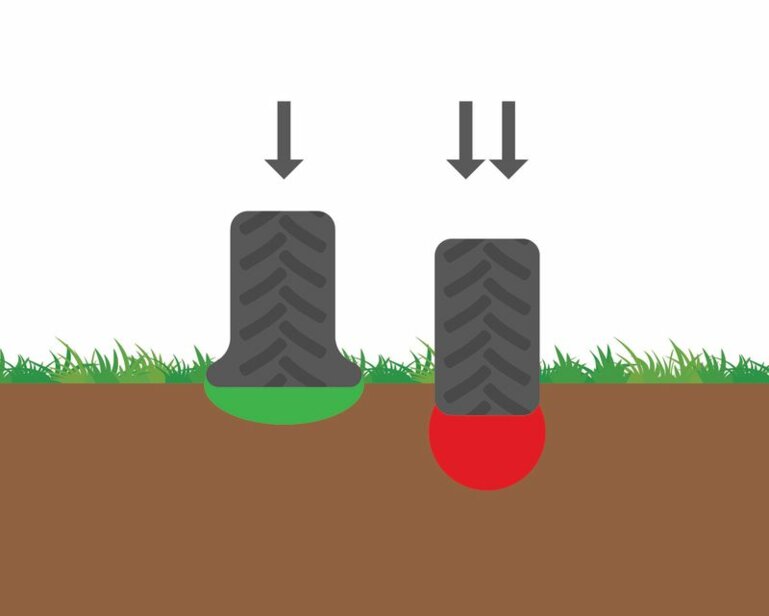

On-land ploughing without soil compaction

The benefits from On-land ploughing are known:

- Limitation of the soil compaction by allowing working with wider and lower pressure tyres.

- Easy removal of the soil compaction since the impact is not in the furrow but in the soil top layer, ploughed instantly.

- Improvement of the soil profile in adverse conditions, especially on heavy soil types.

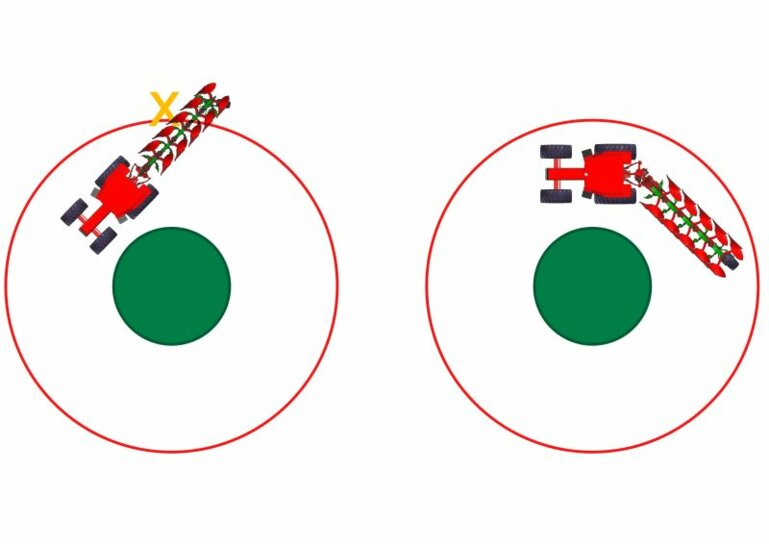

Safer transport (TTS)

Long ploughs like a 10 furrow can imply a safety risk during transport in narrow passes, when coming out of the farm or on roundabouts. Kverneland Trailer Transport Solution (TTS) enables the plough to behave just like a trailer behind a car. It maximises safety for the driver and for anyone or anything around. The pivot point of tractor and plough combination is located in the middle. Therefore, there is no tilting out.

Furthermore, a long plough in transport is often too high to pass under bridges for instance. The Kverneland Ecomat On-land lows down for the optimised height and solves the matter.

Another advantage is the quick and easy made setting. It only takes 1 minute to set the plough from transport to ploughing and vice versa.

High profitability - Low fuel consumption

Scientific studies conclude that a regular plough does not consume more fuel than a cultivator when doing the same work in the same soil conditions at 23 cm working depth.

Author: Prof. Dr. Wolfgang Kath-Petersen Cologne University of Applied Sciences, Institute of Construction Machinery and Agricultural Engineering, 2015

With the Ecomat On-land, the shallower ploughing can only result in an even lower fuel consumption due to lower pulling forces.

Not least, to ensure an efficient control of weeds, slugs and pest, direct drilling would require several extra passes in the field and the extra cost of entrants like chemicals. This is not necessary when shallow ploughing with the Ecomat On-land.

High capacity – low lift requirement

Available as a 8 and 10 furrow implement and a working width adjustable from 30-50 cm, the Kverneland Ecomat On-land can work from 2,40-5,00 m.

With a 65cm interbody clearance, the plough is quite compact and only requires around 7 tons of lift capacity which suits most medium size tractors.

Working width changes

Depending on soil conditions, speed and plant residues, changing the working width helps achieve the best ploughing results. It is easily done by moving only 1 bolt on each leg assembly (30, 35, 40, 45, 50 cm, ie 12”-20”).

Kverneland Ecomat On-land specifications

Kverneland Model |

Number of Furrows |

Working Capacity (m) |

Interbody Clearance (cm) |

Ecomat On-land |

8 - 10 |

2,4 - 5,00 |

65 |

The Kverneland Ecomat On-land benefits from the same steel heat treatments as any Kverneland ploughs already reputed for their robustness, long lasting and low fuel consumption.