u-drill plus 3001, plus 4001

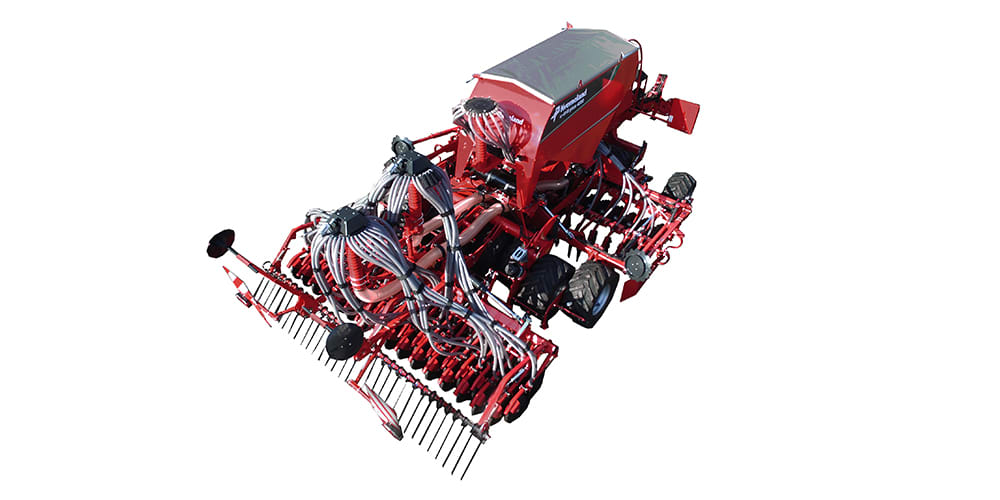

Seeder | Integrated seeding combination

The Kverneland u-drill – the universal seed drill combination

The combined grain and fertiliser model of the trailed universal seed drill combinations carries out seedbed preparation, levelling, reconsolidation, seeding and fertiliser application in one pass.

The advantages of this Integrated seeding combination

- High speed operation (10 – 18km/h)

- Perfect seed & fertiliser placement

- Modular frame concept for flexible adjustment

- Fully ISOBUS compatible

- Easy handling and maintenance

Description

The Kverneland u-drill plus complements the product group of the universal seed drill combination. The u-drill plus carries out seedbed preparation, levelling, reconsolidation, seeding, and fertilising in one pass.

The “plus” stands for the extra feature of the grain and fertiliser version to apply either grain and fertiliser or, alternatively, two different sorts of seeds at the same time. This has been achieved by the divided hopper (40:60) equipped with two metering devices, ELDOS and a hopper capacity of 3000l. The Kverneland u-drill plus is able to deliver fertiliser application rates up to 400kg/ha at 15kph

Features

Features

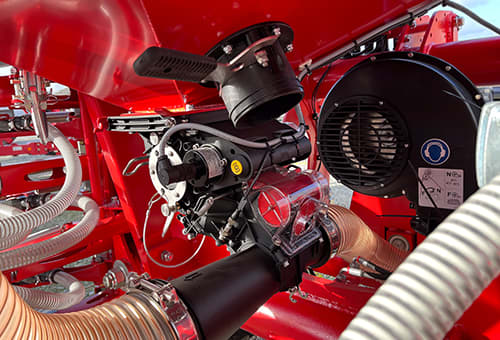

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

Step 1: Level the soil

For the best possible preparation, the front tyre packer levels the soil, crushes large clods and thus paves the way for the optimum depth control of the following tools. The front tyre packer has a diameter of 800mm. When it is not needed, it can be lifted hydraulically, simply by pushing a button..

Step 2: Prepare the seedbed

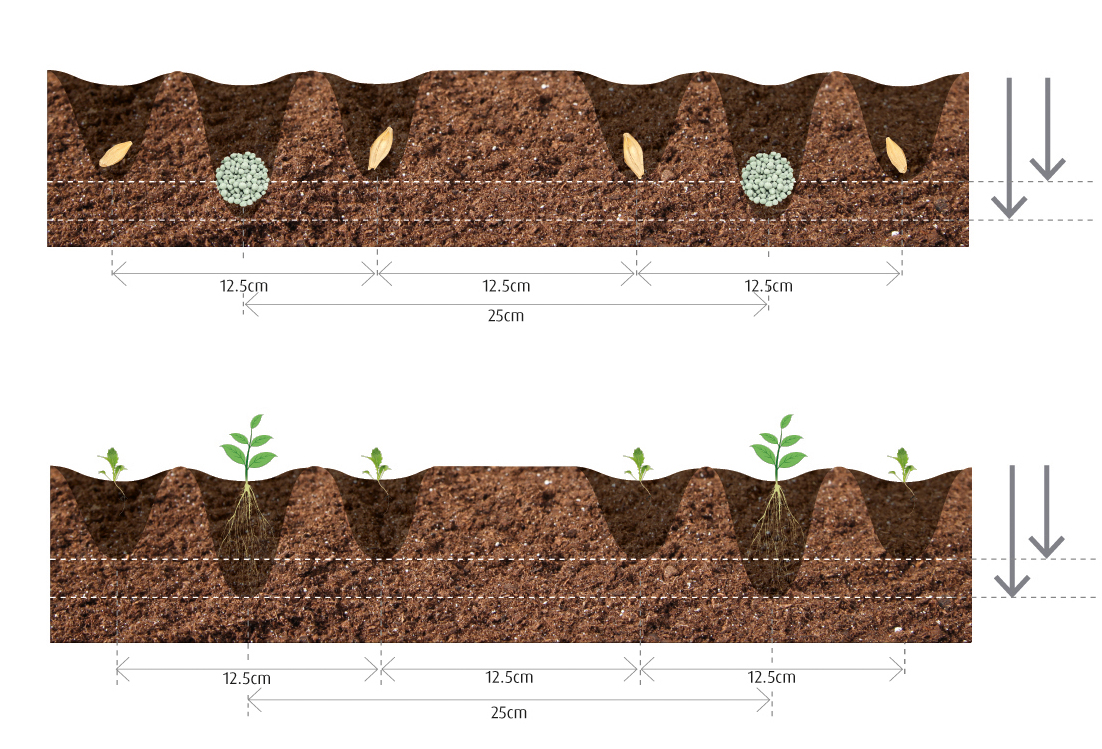

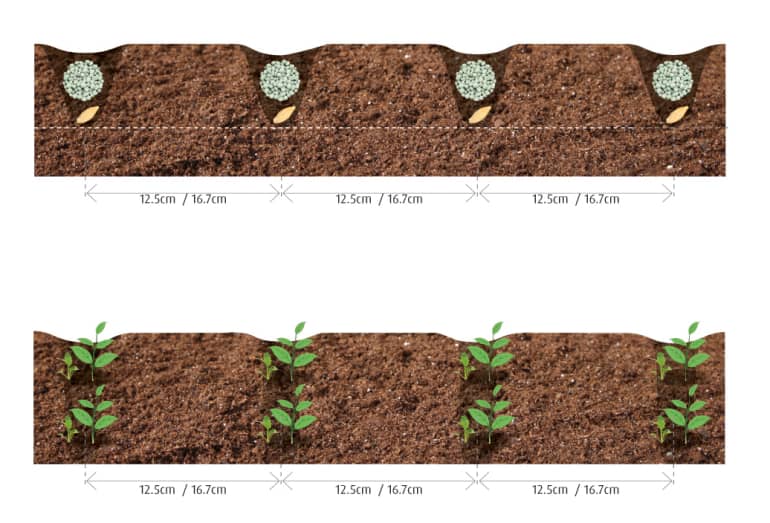

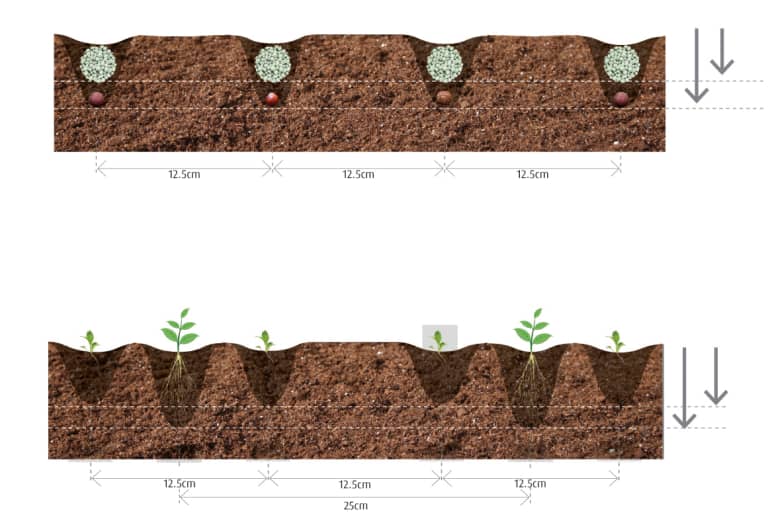

The disc harrow section consists of two rows of aggressively pitched conical discs. The discs are 5mm thick and hardened for long life. Thanks to their conical shape, the cutting angle remains constant. The high rotation speed ensures an excellent cutting quality over the entire working width. The distance between the sowing rows can be 12.5or 16.7cm.

The MD disc section consists of two rows of straight waved discs. The MD disc have been designed for vertical penetration through the flutes. The blade keeps turning, penetrating and cutting even in the most challenging conditions. A seedbed is created only in stripes of 3 to 5 cm in width, in which the seed is placed by the CD coulter.

The MD disc section is available for machines with 16.7 cm row distance and with the u-drill plus in combination with double entry fertiliser injection.

Step 3: First pack, then seed

For perfect depth control of the coulters and an optimum seed-to-soil contact providing excellent capillary action, the loosened soil is re-compacted by a large tyre packer. The large tyre diameter of 900mm significantly reduces the tractive power required by the machine and thus ensures a consistently good work result.

Step 4: Drill and pack at constant seeding depth

The narrow profile of the coulters with their slightly offset steel discs allow easy penetration into the soil. Thus, little pressure is required at this point with only little soil being displaced. The coulter pressure of 100kg can, therefore, be primarily used for the pressing by the integrated press wheels. The result: a uniform seeding depth even at high working speeds! The seeding depth and the coulter pressure can be centrally controlled by the push of a button from the tractor cab – this saves additional time.

The stable depth control and the pressing of the seed produce a capillary system in the soil that ensures access to water and excellent germination

Step 5: Closing

Harrowing the soil completes the drilling. S-shaped or finger harrows ensure an optimum covering of the seeds. The working intensity can be set by the stepless pressure adjustment and at three different angles. To prevent damage to the harrow when reversing, it is equipped with an effective reversing device.

The u-drill plus has been designed for precise fertiliser placement whilst sowing. It is able to apply fertiliser rates up to 400kg/ha (depending on speed and width). The pressurised hopper system of the 6.0m version ensures that these rates are maintained even under the most difficult conditions. Depending on the individual agronomic requirements, the fertiliser can be applied either directly in the seeding row or in between two rows.

Fertiliser placement within the disc harrow section

The outlets within the second row of the disc harrow section apply the fertiliser exactly in between two sowing rows. All plants have exactly the same distance to the incorporated fertiliser placed. By adjusting the working depth of the disc harrow, the depth of the fertiliser placement is determined.

Fertiliser placement within the seeding row

The fertiliser application within the seeding row is done by the double-entry CD coulter. The fertiliser is placed together with the seeds. This is especially suitable for phosphoric fertiliser in order to support the initial germination and development of the plants in the most efficient way.

Sowing of two different crops

The special design of the double-entry CD coulter with two exits also allows the sowing of two different crops in just one working pass.

The u-drill comes with a fully automated headland management system. This saves the driver lots of time and eases the operation. Using just one button, the driver can initiate a headland sequence with wheels, discs and coulter bar all capable of automatic operation in timed stages. The lifting sequence starting with the disc section ensures a constant depth control until the headland.

As the headland sequence starts, the metering device stops automatically – avoiding double seeding. The seed hoses are empty at the headland. This saves up to 5% of seed.

The driver can concentrate on steering the machine and the correct operation. In addition double and/or missed seeding is prevented. With headland management the job can be done more quickly, precisely and efficiently. The drill requires only one double-acting spool to operate.

Step 1: Level the soil

For the best possible preparation, the front tyre packer levels the soil, crushes large clods and thus paves the way for the optimum depth control of the following tools. The front tyre packer has a diameter of 800mm. When it is not needed, it can be lifted hydraulically, simply by pushing a button..

Step 2: Prepare the seedbed

The disc harrow section consists of two rows of aggressively pitched conical discs. The discs are 5mm thick and hardened for long life. Thanks to their conical shape, the cutting angle remains constant. The high rotation speed ensures an excellent cutting quality over the entire working width. The distance between the sowing rows can be 12.5or 16.7cm.

The MD disc section consists of two rows of straight waved discs. The MD disc have been designed for vertical penetration through the flutes. The blade keeps turning, penetrating and cutting even in the most challenging conditions. A seedbed is created only in stripes of 3 to 5 cm in width, in which the seed is placed by the CD coulter.

The MD disc section is available for machines with 16.7 cm row distance and with the u-drill plus in combination with double entry fertiliser injection.

Step 3: First pack, then seed

For perfect depth control of the coulters and an optimum seed-to-soil contact providing excellent capillary action, the loosened soil is re-compacted by a large tyre packer. The large tyre diameter of 900mm significantly reduces the tractive power required by the machine and thus ensures a consistently good work result.

Step 4: Drill and pack at constant seeding depth

The narrow profile of the coulters with their slightly offset steel discs allow easy penetration into the soil. Thus, little pressure is required at this point with only little soil being displaced. The coulter pressure of 100kg can, therefore, be primarily used for the pressing by the integrated press wheels. The result: a uniform seeding depth even at high working speeds! The seeding depth and the coulter pressure can be centrally controlled by the push of a button from the tractor cab – this saves additional time.

The stable depth control and the pressing of the seed produce a capillary system in the soil that ensures access to water and excellent germination

Step 5: Closing

Harrowing the soil completes the drilling. S-shaped or finger harrows ensure an optimum covering of the seeds. The working intensity can be set by the stepless pressure adjustment and at three different angles. To prevent damage to the harrow when reversing, it is equipped with an effective reversing device.

The u-drill comes with a fully automated headland management system. This saves the driver lots of time and eases the operation. Using just one button, the driver can initiate a headland sequence with wheels, discs and coulter bar all capable of automatic operation in timed stages. The lifting sequence starting with the disc section ensures a constant depth control until the headland.

As the headland sequence starts, the metering device stops automatically – avoiding double seeding. The seed hoses are empty at the headland. This saves up to 5% of seed.

The driver can concentrate on steering the machine and the correct operation. In addition double and/or missed seeding is prevented. With headland management the job can be done more quickly, precisely and efficiently. The drill requires only one double-acting spool to operate.

- ELDOS is electric driven by e-bas and e-com, the e-com edition is fully ISOBUS compatible, e-bas works as stand alone controlled system.

- GEOCONTROL by GPS signal is possible which avoids double seeding.

- Special sensors ensure functionality from the tractor cab.

- Five standard rotors are delivered: for fine and large seeds or fertiliser.

- The exchange of the rotors is quickly and easily done without any tools.

- Application rates from 1 to 400kg/ha are possible (depending on working speed and width).

- The metering device is always easily accessible.

Calibration

- Very simple calibration test due to the separate seed guidance.

- A remote control allows the driver to operate the calibration process at the metering device.

- No gear has to be adjusted. The driver simply enters the desired values into the terminal, presses one button to start at the metering device and that’s it.

- The calibration is done automatically.

- A calibration flap with an integrated gate prevents any seed from dropping into the hose.

The u-drill plus has been designed for precise fertiliser placement whilst sowing. It is able to apply fertiliser rates up to 400kg/ha (depending on speed and width). The pressurised hopper system of the 6.0m version ensures that these rates are maintained even under the most difficult conditions. Depending on the individual agronomic requirements, the fertiliser can be applied either directly in the seeding row or in between two rows.

Fertiliser placement within the disc harrow section

The outlets within the second row of the disc harrow section apply the fertiliser exactly in between two sowing rows. All plants have exactly the same distance to the incorporated fertiliser placed. By adjusting the working depth of the disc harrow, the depth of the fertiliser placement is determined.

Fertiliser placement within the seeding row

The fertiliser application within the seeding row is done by the double-entry CD coulter. The fertiliser is placed together with the seeds. This is especially suitable for phosphoric fertiliser in order to support the initial germination and development of the plants in the most efficient way.

Sowing of two different crops

The special design of the double-entry CD coulter with two exits also allows the sowing of two different crops in just one working pass.

Technical specifications

Technical specifications

Download brochure| Model | u-drill plus 3001 | u-drill plus 4001 | |

|---|---|---|---|

| Frame | rigid | rigid | |

| Working / transport width (m) | 3.0 | 4.0 | |

| No. of metering devices | 2 | 2 | |

| Hopper capacity (I) u-drill plus | 3,000 | 3,000 | |

| Required oil volume | > 90l/min | > 90l/min | |

| Single-acting hydraulic valve + zero-pressure return for fan drive | Standard | Standard | |

| 1 x double-acting hydraulic valve for machine control | Standard | Standard | |

| Power requirement 12 V > 70 A | Standard | Standard | |

| No of CD double disc coulters (16.7/12.5cm) | (18/24) | (24/32) | |

| CD double entry seed outlet | Option | Option | |

| Coulter pressure up to 100kg | Standard | Standard | |

| Electro-hydraulic adjustment of the seed placement depth via ISOBUS terminal | Standard | Standard | |

| Press wheels (Ø 380 x 50mm) | Standard | Standard | |

| Row spacing | 12.5cm or 16.7cm | 12.5cm or 16.7cm | |

| Electronic adjustment of the seed quantity with radar | Standard | Standard | |

| Filling level sensors in the seed hopper (no.) | Standard (2) | Standard (2) | |

| Fan speed sensor | Standard | Standard | |

| Metering device monitoring | Standard | Standard | |

| Electronic half-width shut-off | Option | Option | |

| Mid-mounted front packer (Ø 800mm) | Option | Option | |

| Complete front packer (Ø 800mm) | - | Option | |

| Electro-hydraulic adjustment of the disc harrow depth via ISOBUS terminal | Standard | Standard | |

| Disc harrow (Ø 460mm) with application tube | Standard | Standard | |

| MD disc (Ø 430mm) 16.7cm seed distance | Option | Option | |

| Offset tyre packer (Ø 900mm) | Standard | Standard | |

| Maintenance platform, road transport lights | Standard | Standard | |

| Hydraulic fan drive | Standard | Standard | |

| Lower link cross shaft CAT. III N (825mm) | Standard | Standard | |

| Lower link cross shaft CAT. III (965mm) | Option | Option | |

| Hydr. clod board | Option | Option | |

| S-shaped seed harrow 10mm | Standard | Standard | |

| Finger harrow 12mm | Option | Option | |

| Calibration set | Standard | Standard | |

| Hydraulical folding track marker with notched discs | Option | Option | |

| Track eradicators (2 tines per track) | Option | Option | |

| Pneumatic brakes | Option | Option | |

| Hydraulic brakes | Option | Option | |

| Extended drawbar for tractors with twin tires up to 4.5m | Option | Option | |

| Pre-emergence marker (centre marking) | Option | Option | |

| Soil flow harrow | Option | Option | |

| LED work lights | Option | Option | |

| IM Tellus PRO /Tellus GO+ for non-ISOBUS-capable tractors | Option | Option | |

| IM Tellus PRO / Tellus GO+ for ISOBUS tractors | Option | Option | |

| Hopper volume weighing system with separate monitor | Option | Option | |

| Seed flow sensors | Option | Option | |

| Headland management | Standard | Standard | |

| Weight (kg) (with front packer + track eradicators) | 4800 | 5,600 | |

| Min. power requirement (HP) | 95 | 120 |

Technical specifications

Technical specifications

Download brochureWorking Width |

Row distance (cm) |

Weight (kg) with front packer + track eradicators |

|

u-drill plus rigid |

3.0m |

12.5 / 16.7 |

4,800 |

u-drill plus rigid |

4.0m |

12.5 / 16.7 |

5,600 |

u-drill plus folding |

4.0m |

12.5 / 16.7 |

5,600 |

u-drill plus folding |

6.0m |

12.5 / 16.7 |

8,400 |