Kverneland 8590

Tedder | 3pt Mounted Tedder

Productivity at the core

Heavy duty mounted tedder with compact transport dimensions

The advantages of this 3pt Mounted Tedder

- Maintenance-free in season, except PTO

- Strong driveline including HexaLink finger clutch

- Sturdy design - V-shaped central unit

- Central adjustment for border spreading

- Largely dimensioned oscillation dampers

Description

Kverneland 8590, with 9.0m working width, is designed to perform perfectly in all crop conditions, with a minimum of non-productive maintenance required and with diminished transport dimensions. Featuring a heavy-duty fully closed headstock this machine will fit perfectly into the operation of professional farmers, looking for a strong, effective, and versatile tedder. This tedder is fitted with a high performance driveline combination. The complete driveline is maintenance-free, and offers highly reliable transfer of power, combined with extremely compact transport. The highly flexible frame secures perfect contour following, also in demanding conditions.

Highlights

- Fully maintenance free in season except PTO.

- Strong driveline, sturdy u-joints on the inside rotors and flexible HexaLink finger clutch on outside rotors.

- Strong and sturdy design with closed V-shaped central unit.

- Central adjustment for border spreading keeping the crop inside the field.

- Largely dimensioned oscillation dampers for excellent running characteristics.

- Optional headland kit for easy lifting on headlands.

Features

Features

Powered by a maintenance-free driveline and gearboxes, focus can be directed towards the essentials to maximise productivity. No time is wasted on time consuming greasing. Additionally the hinges are connected with strong maintenance-free roller bearings for extended longevity and stability of the connection points.

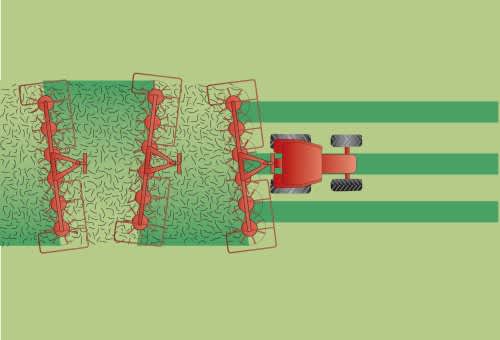

These machines offer very compact transport dimensions with their clever folding solution. A parking height below 4.0m is possible, due to the implementation of the new HexaLink finger clutch system in the joints of the two outer rotors. The remaining rotors are driven by maintenance-free double universal joints, for strong and efficient transfer of power.

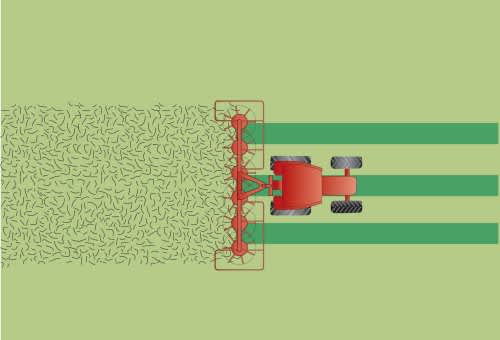

To increase productivity, the Kverneland tedders can be equipped with a mechanical or an optional hydraulic border tedding device (hydraulic headland kit). A marker cleverly shows the position of the axle.

Kverneland's new generation of mounted tedders are designed to perform perfectly in all crop conditions, with a minimum of non-productive maintenance required. Featuring a heavy-duty fully closed headstock and a strong V-shaped central unit, the machine will fit perfectly into the operation of professional farmers, looking for a strong, effective, and versatile tedder.

- Kverneland oscillation dampers ensure excellent ground contour following and tedder flotation.

- The construction of the oscillation dampers results in a smooth and even distribution of the grass, thanks to the constant tine distance from the ground.

- Widely spaced mounting points - no risk of ‘hunting’.

- Excellent running characteristics.

- Low-positioned linkage on the headstock, for more effective damping action during transport.

- No risk of the tedder running under the tractor on downhill work, excellent tedding at all times through constant tine spacing to the ground.

Powered by a maintenance-free driveline and gearboxes, focus can be directed towards the essentials to maximise productivity. No time is wasted on time consuming greasing. Additionally the hinges are connected with strong maintenance-free roller bearings for extended longevity and stability of the connection points.

These machines offer very compact transport dimensions with their clever folding solution. A parking height below 4.0m is possible, due to the implementation of the new HexaLink finger clutch system in the joints of the two outer rotors. The remaining rotors are driven by maintenance-free double universal joints, for strong and efficient transfer of power.

Kverneland's new generation of mounted tedders are designed to perform perfectly in all crop conditions, with a minimum of non-productive maintenance required. Featuring a heavy-duty fully closed headstock and a strong V-shaped central unit, the machine will fit perfectly into the operation of professional farmers, looking for a strong, effective, and versatile tedder.

To increase productivity, the Kverneland tedders can be equipped with a mechanical or an optional hydraulic border tedding device (hydraulic headland kit). A marker cleverly shows the position of the axle.

- Kverneland oscillation dampers ensure excellent ground contour following and tedder flotation.

- The construction of the oscillation dampers results in a smooth and even distribution of the grass, thanks to the constant tine distance from the ground.

- Widely spaced mounting points - no risk of ‘hunting’.

- Excellent running characteristics.

- Low-positioned linkage on the headstock, for more effective damping action during transport.

- No risk of the tedder running under the tractor on downhill work, excellent tedding at all times through constant tine spacing to the ground.

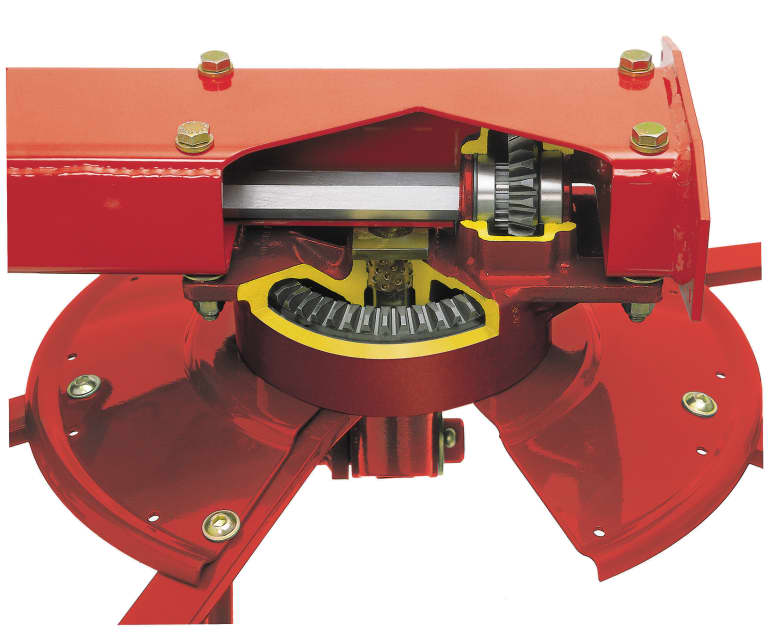

- The ProLine gearbox is a strong and reliable construction, and is not fitted to the mainframe.

- Shock-protected: The enclosed system is not affected by chassis or tine arm vibrations.

- Constant lubrication: Enclosed and oil-immersed, the gearbox components enjoy extended longevity over systems that require manual lubrication.

- Reduced maintenance: There is no need for daily lubrication.

- Environmental protection: No lubrication means no leakage - hence higher-quality forage.

- No corrosion: No ingress of dust and water, not even during pressure washing.

Technical specifications

Technical specifications

Download brochure| Model ProLine | 8590 | |

|---|---|---|

| Working width (m/ft) | 9.00 / (29’6”) | |

| Number of rotors | 8 | |

| Number of tines/rotor | 6 | |

| Transport width (m/ft) | 2.94 / (9’8”) | |

| Transport length (m/ft) | 2.16 / (7'1") | |

| Storage height (m/ft) | 3.49 / (11’5”) | |

| Capacity theor. (ha/h) | 7.2 |

Technical specifications

Technical specifications

Download brochureWorking Width |

Rotors/Tines |

Weight |

|

8555 |

5.50m |

4/7 |

620kg |

8568 |

6.80m |

6/6 |

900kg |

8576 |

7.60m |

6/7 |

980kg |

8590 |

8.90m |

8/6 |

1260kg |

85112 |

11.20m |

10/6 |

1600kg |