Plough - Get Ready For Next Season

Helpful tips and tricks to get your plough prepared to operate at it’s maximum capacity through the season.

Be prepared for the coming season - by giving your Kverneland Plough a Health Check and ensure that you have sufficient stocks of essential wearing parts. Keep down time to a minimum by contacting your local Kverneland dealer and take advantage of the Special Out of Season prices on Original Parts.

Check all wearing parts and renew if worn

Grease all bearings and pivot shafts

Ensure Auto Reset springs are correctly adjusted to 70cm

Ensure all skimmers are correctly set

Check Vari width Bushes and cones – replace if worn

Check Hydraulic hoses and connections. Replace if necessary

Check front linkage pins and renew if worn

Ensure front slide rails are clean and greased

Thanks to our unique heat treatment processes, our steel guarantees long lasting mouldboards with unique benefits to give you maximum value for money.

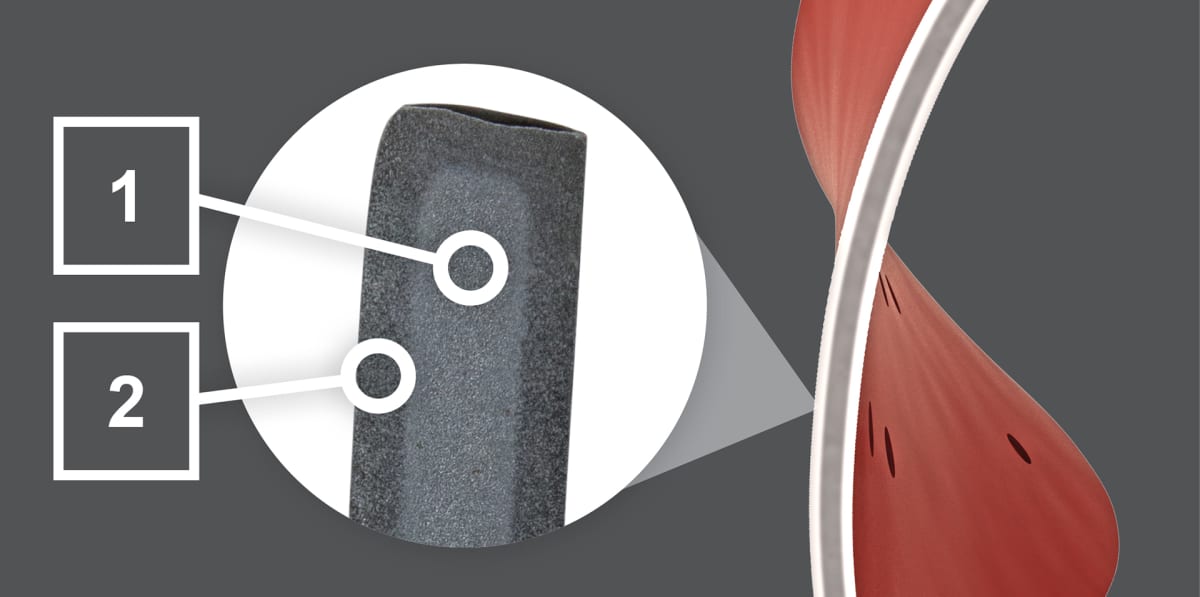

Cross section of a mouldboard

1. Soft and flexible core to avoid breakage.

2. Hard surface for less friction and longer lifetime.

All our points and shares are specially heat treated using Kverneland’s unique Zone Hardening method. Improving the quality of the steel and protecting the area around bolts holes are key factors to achieving top performance and long life time.

Infrared camera: heat treatment

1. Extremely hard wearing zones.

2. Area around bolt holes flexible to avoid breakages.

For ploughs fitted with Kverneland’s unique Auto Reset system, we recommend that you loosen all the leaf springs before winter storage. Releasing the spring tension when not in use will increase lifetime of the springs.

At the beginning of the season remember to adjust and tighten the leaf springs to a distance of 70 cm between the pins. It is also important to lubricate the grease nipple of each beam to maintain the correct plough leg release.

The standard Auto-Reset system includes 7 Kverneland heat treated leaf springs. For heavier to extreme soil conditions, extra leaf springs may be added to withstand higher resistance before releasing the plough legs.

640 kg release force

KK060709

900 kg release force

KK060703

1100 kg release force

KK060703 (1x)

KK057068 (2x)

1400 kg release force

KK060703 (1x)

KK060714 (1x)

Time is money, and we know the importance of receiving the right parts at the right time! Your Kverneland dealer is supported by a massive distribution network to supply you with exactly what you need, when you need it.

Our main distribution centre Metz warehouse is located in Thionville, France. A strategic location for distributing parts to all corners of the world. With over 70.000 parts in stock and 24/7 service, we are ready to supply you with parts – at any time!