SelfLine 4.0 System 1000+

Hopper capacities from 25m³ to 32 m³.

Description

The Kverneland Siloking SelfLine 4.0 System 1000+ models impress with high manoeuvrability, capacity and performance and have been designed for farms with 1,000 cows and more. Thanks to the 3-axle chassis, the self-propelled feed mixer can be loaded with up to 12 tonnes – and the load on the chassis, the tires and the driving surfaces is reduced.

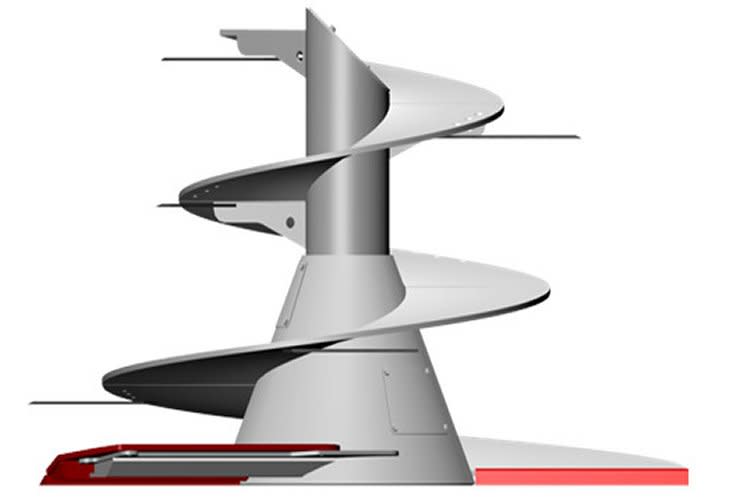

In addition, the active steering of the front and rear axles offers an enormous manoeuvrability. The mixing hopper has a capacity of 32 m³, 29m³ or 25 m³ and 3 or 2 turbo augers. And the XXL self-propelled mixes very quickly and homogeneously.

Features

Features

- The highly versatile steering system of the Dyna-power chassis makes the machine very manoevrability and flexible in spite of its’ size.

- Steered axles provide the Prestige 3024 with a turning radius of only 5.75m or 8.10m.

- The 3 axles are designed for unrivalled loading capacity and driving stability.

- The standard air suspension is designed for excellent road contact and unique driving comfort of up to 40km/h.

- The 2m wide milling head is designed to manage the flow of feed material as fast and as gently as possible.

- The tungsten carbid knives are specially shaped to collect feed as efficiently as possible.

- Each knife has a proven long life– but is also reversible to extend the life even further.

- Immediately behind the knives are specially designed shovels, which gently move the feed to the centre of the milling head and onto the loading conveyer, transporting the feed into the mixing chamber

- Auger height is adjusted to hopper height for the perfect auger-hopper ratio.

- Generously dimensioned Turbo auger with slow revolution for gentle mix at low power requirements.

- Additional wings on the auger add to a rapid and thorough mixing action.

- Optional magnet available for removing foreign iron particles from the feed

- For longer durability Siloking Kverneland has developed SILONOX lining as an option for the mixing augers and hopper walls, where most wearing occurs

- The unique three-point chassis design avoids running over the feed.

- various discharge options:

- Simultaneous discharge at either side

- Foldable discharge conveyor for direct feeding into high throughs

- Optional discharge door at front.

- Easily operated from the cab.

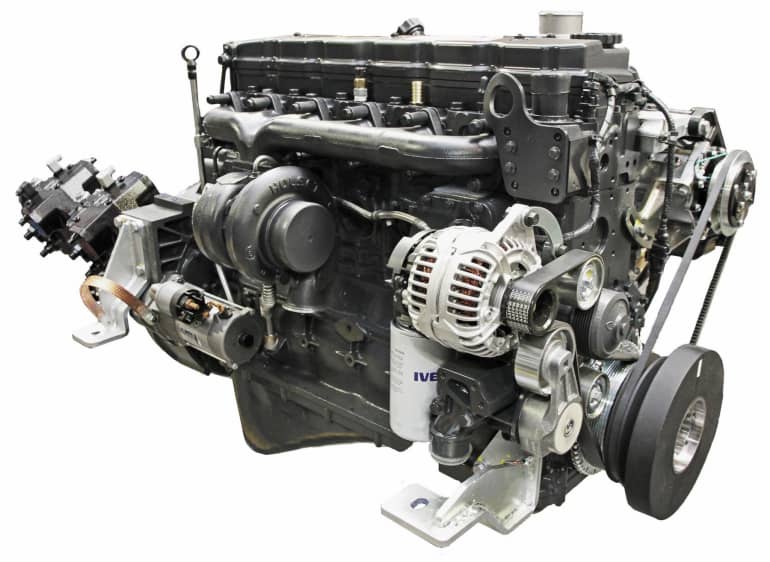

- The new common rail SCR engine technology ensures that the Prestige mixers match the latest standards.

- Performance of the driveline is matched exactly to the capacity of milling head and mixing unit.

- The engine is positioned strategically at the centre of the mixer, close to both milling head and mixing unit, to ensure the most efficient power distribution.

- Simple maintenance with easy access to the engine compartment.

- Professional air filter system.

- The carefully designed controls are all within easy reach of the comfortable suspended seat.

- The multifunction joystick provides most of the controls for loading and discharge.

- The cabin position and the extended windscreen ensure a clear view of the loading process – the milling head is clearly visible from the highest to the lowest position.

- Heated mirrors, good air circulation inside the cabin and large wipers help to maintain maximum visibility from the cabin – even when the difference in temperature inside and out is significant.

- Cabin heater re-circulates the air from the bottom – ensures clear windscreen (and warm feet!)

- The suspended seat also makes even the longer daily tasks pleasant and comfortable.

Technical specifications

Technical specifications

Download brochureModel |

Capacity (m³) |

Length (m) |

Width (m) |

Height (m) |

System 1000+ 3225-25 |

25 |

9.46 |

2.55 |

3.53 |

System 1000+ 3225-27 |

27 |

9.46 |

2.71 |

3.58 |

System 1000+ 3225-29 |

29 |

10.60 |

2.55 |

3.33 |

System 1000+ 3225-32 |

32 |

10.60 |

2.55 |

3.50 |