Models going to work include 5f/100 and 6f/85 formats, with ploughs chosen for their ability to deliver repeatable accuracy thanks to FURROWcontrol.

With ISOBUS technology at its core, the 2500-series i-Plough enables easy adjustment of plough settings. From an in-cab terminal, operators can set left and right-hand turnover angle; straighten furrows using an A-B line; set the plough for marking out; and swap from transport to work modes - all at the touch of a button.

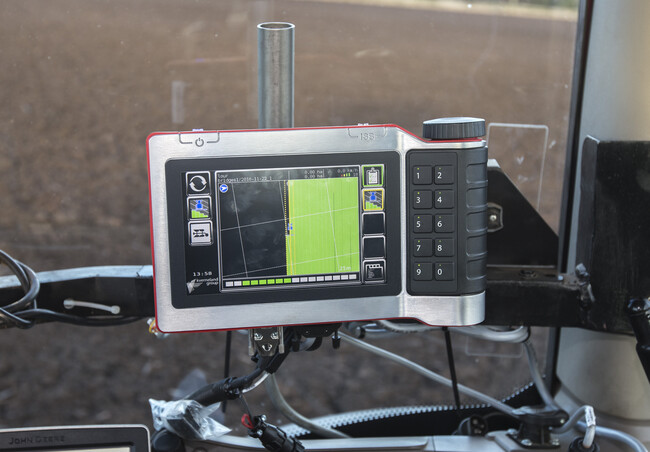

Tellus GO terminal offers easy control of i-Plough functions.

FURROWcontrol is a software application developed by Kverneland’s Mechatronics Centre that combines hydraulic vari-width and ISOBUS to automatically manage the i-Plough’s furrow width during ploughing. It follows A/B lines and uses a GPS signal to automatically open and close the working width of the plough as it travels across a field. Doing so is said to remove any bend from the ploughing, and is guaranteed to maintain a straight line, even when ploughing in the dark.

One of the first to go to work is that bought by Lour Farms in Angus, and supplied by Netherton Tractors. Farm manager Mike Cumming places a lot of importance on primary cultivations, and demands a high quality finish at every stage of crop production for the 2,000-acre operation based at Ladenford. “The i-Plough is the ideal implement to deliver arrow-straight furrows in all conditions,” he says. “Technology makes life easier for my operator, and with 600 acres of winter ploughing, we can achieve a superior finish that lets us make the most of frosty conditions.”

Lour Farms manager Mike Cumming (left) with operator Michael Hiddleston.

“When working across sloping fields for example, we can tweak the plough angle on-the-move to ensure that furrows are rolled over properly,” he adds. “We do value how our farm looks, and the ability to achieve a high quality finish across all our soil types is essential.”

Michael Hiddleston says it is easy to adjust the plough angle on-the-move to help roll furrows uphill when ploughing across slopes.

The Kv 2500-series features folding head-stock design and a cross-shaft that can be unlocked for steering, and these innovations allow the plough to behave like a trailer on the road. Available in five and six-furrow formats recommended for tractors up to 280hp, the 2500-series uses an all new Aero-profile hollow leg design that contributes to increased under-beam clearance and better flow of residues; new skimmers; and a range of depth wheel designs, including a rubber tracked option that sits below the plough frame.

4th January 2017