XHD CARBIDE REINFORCED PLOUGH PARTS

The new XHD Carbide parts are your perfect weapon against highly abrasive soil.

Kverneland’s XHD plough parts are designed with the most extreme conditions in mind. Abrasive soils put significant stresses on earth wearing parts, resulting in fast wear and regular parts replacement. Thus increasing both costs and downtime.

The Kverneland XHD Carbide range is the ideal solution that makes light of tough and demanding conditions. Each part is reinforced by embedding specially shaped tungsten carbide tiles on strategic places that are exposed to hard wearing. Especially suited to large farms and contractors, the new XHD range has a lifetime up to 10 times the life* of the standard parts, keeping costs and downtime to a minimum. A cost effective alternative to handle the toughest conditions.

*Based on average test conditions. Depending on soil type, moisture content, machine type, working speed, working depth, machine width and mounting position.

Tungsten Carbide is one of the hardest materials known to man. Combining Carburised Tungsten Powder with Soft Cobalt produces a long lasting, hard and durable material able to withstand extreme impacts.

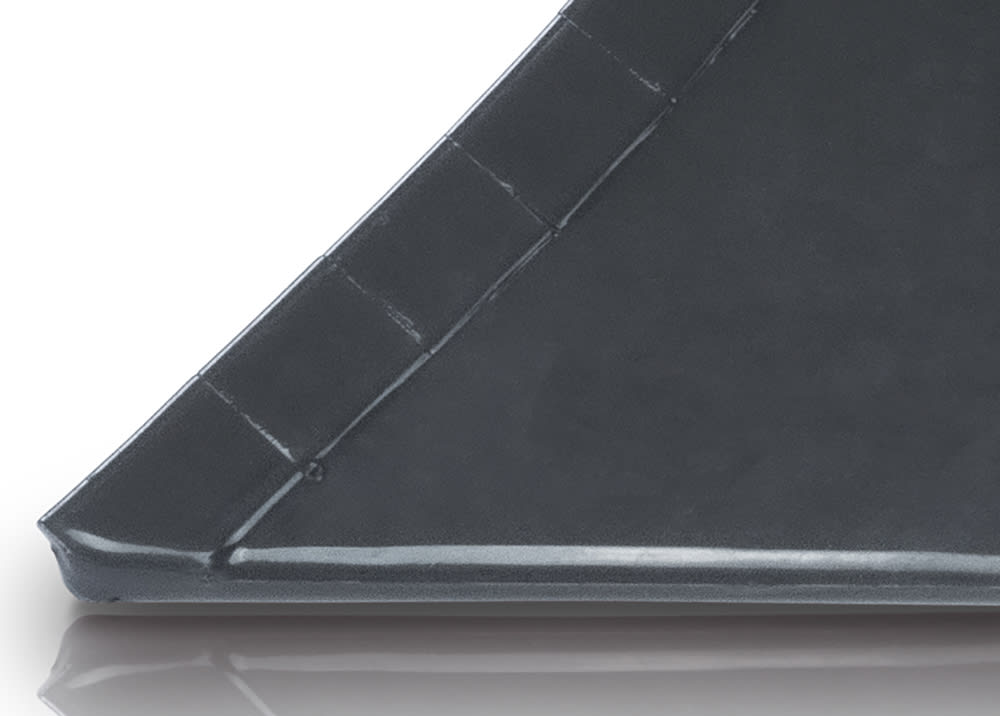

A Premium Grade of Tungsten Carbide tiles are applied to Kverneland XHD parts to protect key areas against breakage and fast wearing.

The function of each XHD part is different and as such, each experiences different stress levels and impacts. To achieve an acceptable balance between long life verses cost, whilst retaining its high wear characteristics and resistance to impacts - each part has a unique balance between hardness and flexibility.

Many reinforced Non Genuine parts are not heat treated, but rely solely on the Tungsten Carbide protected areas. In Kverneland, we understand the importance of balancing the correct heat and hardness and apply the same tried and proved methods to all our XHD parts.

To allow a frictionless flow of soil, our unique heat treatment produces a harder and smoother surface that lasts longer than softer, untreated steel. The ideal combination of Tungsten Carbide tiles on heat-treated steel gives you the best weapon to face the most extreme soil conditions.

The traditional method of reinforcing steel parts is to apply flat tungsten carbide tiles to the surface of the cutting edge. However, these only protect the surface - not the cutting edge.

All cutting edges of the Kverneland XHD range are equipped with Corner Tiles. These specially designed tiles wrap around the leading edge, protecting both the surface and edge from wear and damage. The result is a sharper, long lasting edge – that remains resistant to shocks and breakages from hard impacts.

The XHD Carbide point is protected with 5 premium grade tungsten carbide tiles. 3 specially designed corner tiles are located along the leading edge and retain their specific shape and strength to give maximum protection against hard impacts and abrasive soils. In addition, 2 tiles have been placed on the upper side of the point to protect the zone particularly exposed to wear. At last, but not least, the XHD Carbide point has a special shape to ensure a very good soil penetration, even in the driest and hardest soil conditions. The XHD Carbide point will fit on the XHD Carbide share but also any other

Original Kverneland share which accepts standard Kverneland reversible point.

XHD CARBIDE POINT*

A152081130 - Left, bolts included

A152081030 - Right, bolts included

*XHD Cabide points fits body no. 8, 9, 25, 28, 38. Will fit on Standard reversible shares and CLC/CTC stubble cultivators.

The XHD Carbide shares are protected with 17 (16” share) and 20 (18” share) premium grade tungsten carbide corner tiles. Located along the full leading edge of the share, the tiles retain their shape and strength to give maximum protection against hard impacts and abrasive soils. The shares are designed to be a seamless link between the point and mouldboard and ensure a smooth flow of soil over the whole plough body with minimum friction, resulting in longer lifetime.

XHD CARBIDE 16” SHARE*

A152081730 - Left, bolts included

A152081630 - Right, bolts included

XHD CARBIDE 18” SHARE*

A152081930 - Left, bolts included

A152081830 - Right, bolts included

*XHD Cabide shares fits body no. 8, 9, 25, 28, 38

The XHD Carbide skimmer share is protected with both tungsten carbide tiles and PTA (plasma transferred arc) hard facing. Located on the horizontal cutting edge, the 11 specially designed premium grade tungsten carbide corner tiles retain their shape and strength to give maximum protection against hard impacts and abrasive soils. In addition, a strip of PTA to the vertical edge gives added protection against aggressive conditions.

XHD CARBIDE SKIMMER SHARE

A133949530 - Left, bolts included

A133949430 - Right, bolts included

The XHD Carbide shin piece is protected with 11 premium grade tungsten carbide corner tiles that retain their shape and strength to give maximum protection against hard impacts and abrasive soils. Located on vertical leading edge the tiles retain their shape and strength to give maximum protection against hard impacts and abrasive soils, whilst ensuring an even flow of soil and protection to the base of the mouldboard.

XHD CARBIDE SHIN PIECE*

A133939530 - Left, bolts included

A133939430 - Right, bolts included

*XHD Cabide shin piece fits body 8 and 28.

Time is money, and we know the importance of receiving the right parts at the right time! Your Kverneland dealer is supported by a massive distribution network to supply you with exactly what you need, when you need it.

Our main distribution centre Metz warehouse is located in Thionville, France. A strategic location for distributing parts to all corners of the world. With over 70.000 parts in stock and 24/7 service, we are ready to supply you with parts – at any time!