Kverneland Turbo T i-Tiller

Smart Farming Cultivator

Highlights

Automatic site-specific tillage Versatile - from shallow to medium Complete cutting, perfect mixing & levelling Low pulling force needed Large performance at high speedDescription

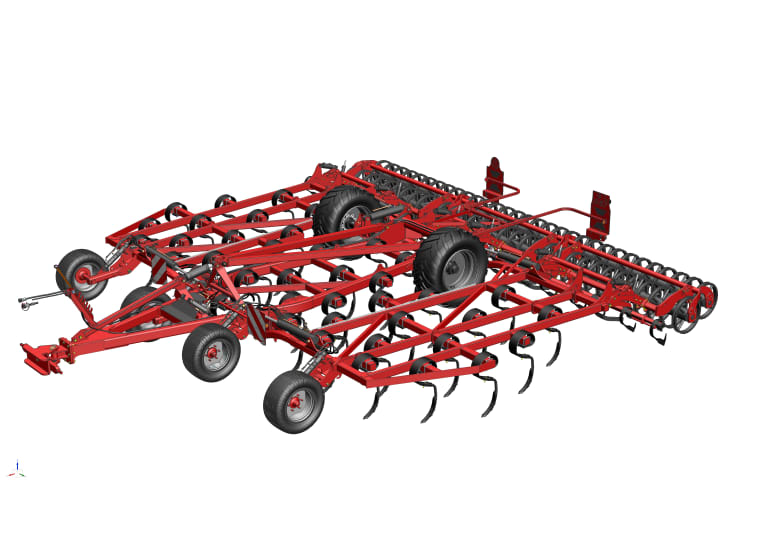

The Kverneland Turbo T i-Tiller has been designed to provide the best working quality with the highest output, whilst ensuring the lowest costs of operation.

Efficient and sustainable

The depth of compaction, soil types or soil moisture can vary greatly with one field. Site-specific tillage by the Turbo T i-Tiller will adjust the intensity and depth of the cultivation as needed for a good soil structure and healthy plant growth. This will lead to economic savings and, moreover, protect the soil and the environment.

With the Turbo T i-Tiller, the depth- and levelling adjustments are directly controlled from the tractor cab by the ISOBUS terminal. The working depth and the height of the levelling equipment are easily adjusted by pressing a button on the terminal. Automatically, the Smart System of the Turbo T i-Tiller starts to set up all hydraulic cylinders! A front/rear depth adjustment can be done at any time and on the move depending on soil conditions.

The On-The-Go Dynamic Traction Control transfers weight from the front gauge wheels to the tractor coupling in order to give more grip and traction to the tractor. In hilly conditions, the pressure is constantly adjusted to maintain always the selected pressure. The result is less fuel consumption, less wearing of the tires by slipping control and a better soil structure by avoiding compactions.

The overload protection system Auto-Protect reacts to obstacles or lateral forces (right/left or both together). The Smart System lifts up the machine if values excess a specific significant level e.g. if the operator misjudges the affected forces on the machine or misuses it by turning the machine without lifting or over reaching the highest pulling force. This guarantees a longer lifetime and a better second hand value.

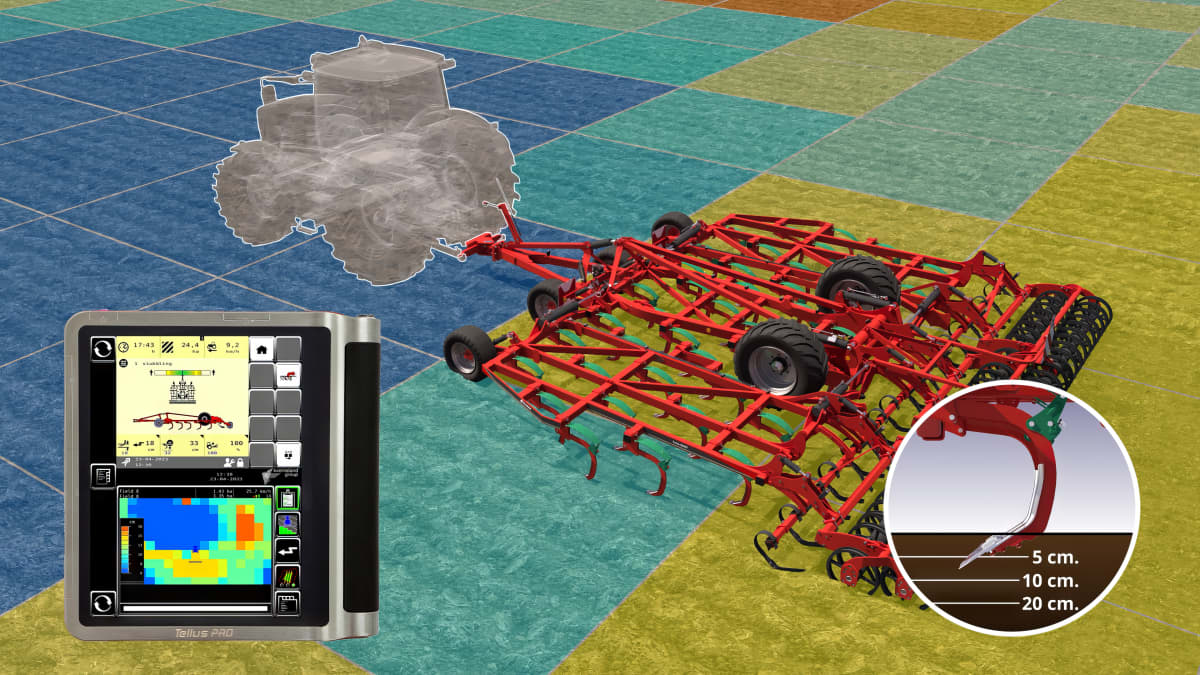

Automatic site-specific depth control on the go based on application maps

With the GPS GEOCONTROL steering of the Kverneland ISOBUS Turbo T i-Tiller via application maps, all depth adjustments are completely self-steering which allows various depth settings within one field and increases operators comfort and efficiency. The sequence of actions inside the cultivator itself are synchronised. Depth guidance wheels in the front and the rear roller are connected and automatically steered. The machine stays always parallel to the ground and acts as one section. Where the largest part of the machine is in a dedicated depth zone defined via the application map, the depth is taken. Adapting the intensity of the cultivator to the individual conditions will increase the efficiency by saving fuel, extending the lifetime of wearing parts and of the complete implement. It also protects the soil, which contributes to sustainable farming.

Features

3 steps to get a fine seedbed ready

-

Tillage the soil

The Kverneland Turbo T i-Tiller is offering a 4 row configuration on the mounted machines and even 5 rows of tines on the trailed version. In combination with the 19cm tine distance, this leads to a nice mixing and finishing without the risk of blockages. The Turbo T i-Tiller can be equipped with two different tines (Reflex tine or C-tine) and a variation of shares to adjust the machine to different conditions and tasks. -

Levelling the soil

The Kverneland Turbo T i-Tiller is offering the choice between a levelling tine and a disc system. Both units are spring-loaded and can be adjusted in their aggressiveness. Also the angle to the ground can be adjusted. In combination with special border equipment, a perfect levelling is achieved. -

Recompacting the soil

The third step of perfect seedbed preparation is soil recompaction. Therefore, a wide range of rollers are available to meet the various conditions and requirements.

Advanced testing program

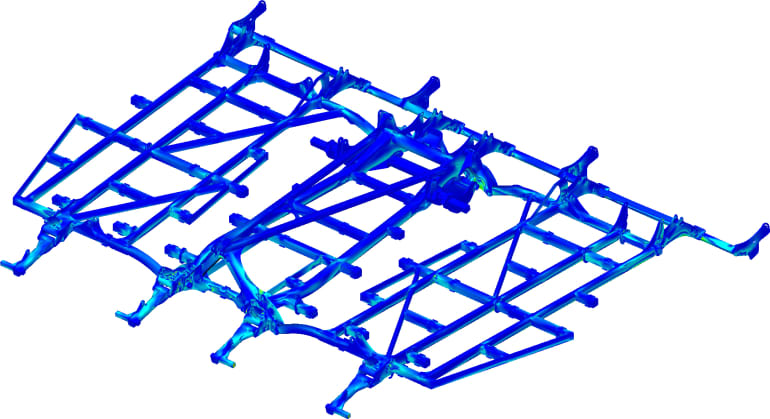

Before the Turbo was launched into the market, it had passed a whole series of tests to ensure the impeccable quality of the product.

• Sophisticated technologies are used for each development such as static load test, finite elements method (FEM) and shake-lifetime tests.

• Finally the machines are tested in the field under different conditions to reconfirm that the requirements to all functions and strength are met. A strict LOR is defined to meet all kind of soil conditions.

The frame is a result of a long study made by FEM (Finite Element Method) calculation to optimise the steel over the working width and proposing a strong structure able to resist to tractors up to 450hp for the trailed model, up to 300hp for the Turbo F and up to 175hp for the rigid frame.

The complete Turbo range has been designed to be combined with the Actipack roller, which is the heaviest roller in the range. All the most agressive scenarios (deep working when turning, headland turns, transport tests, ...) have been considered to make the different frames as strong as possible and thus guaranteeing the proven Kverneland quality.

High vibration for intensive mixing and crumbling

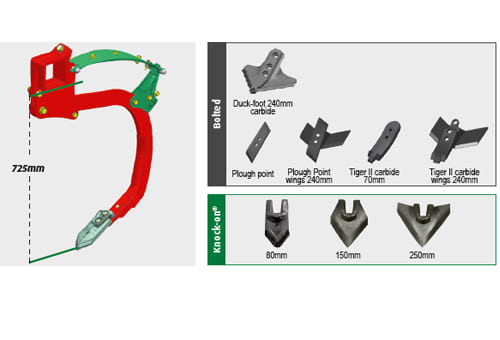

Reflex tine: versatile for all conditions

The Reflex tine benefits from high vibration effect: the large coil and the high tine clearance of 725mm gives a high flexibility whilst ensuring a high vibration effect to crack the clods and mix the soil. The working depth of the share stays even when the tine release to the back thanks to its stable design. The narrow tine spacing ensures active crumbling and perfect levelling. Thus the pressure applied on the coil is reduced to extend its life time.

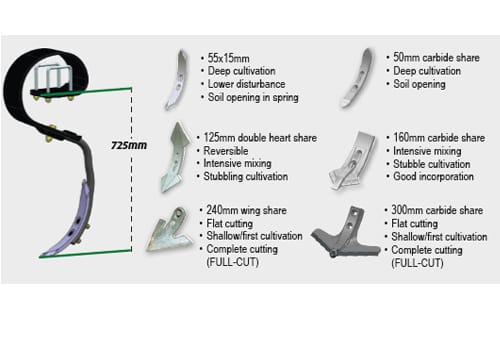

The Reflex tine is the perfect solution for using the Turbo in first/second stubble pass or for seedbed preparation. Also for the incorporation of slurry or manure the Reflex tine is the best choice. To make it even more versatile three different shares are available

For stony condition and high penetration

Triflex tine 400: High stability at deep operations

The auto-reset Triflex tine 400 uses the well known Kverneland leaf spring system to ensure a high point pressure of 400kg in work and a smooth release curve when the tine hits an obstacle. The Triflex tine 400 with narrow design and special shape reduces the pulling forces while ensuring a perfect penetration in most compacted soil. It is the perfect choice for deep loosening and working on heavier soil types strewn with stones.

The Triflex tine 400 can be equipped with different shares to adapt to different working depths and tasks. 3 types of shares are available with the patented Knock-on® system. It is the easiest way of changing parts on a cultivator, either to adapt the machine to the job to be done or to change wearing parts.

Leaving an even surface

In order to create an even surface for a fine seedbed, Kverneland offers various options of levelling tools for the Turbo.

There are levelling tines which are a very easy and economic way of levelling and to handle normal straw conditions on light to medium soil types.

When it comes to heavy amounts of residues and also more clay or loamy soils the levelling discs are more suitable.

Both versions are overload protected by a spring to avoid damages in stony or other difficult conditions. Individual springs ensure individual release of tines or discs and keep levelling quality even in stony conditions. The pressure on this spring and also the angle of the levelling discs/tines can be adjusted for a perfect results.

To respect the transport width on the Turbo mounted versions with 3.00 and 3.50m working width the outer tines/discs can be hydraulically or mechanically folded in.

The clod board in front of the trailed models increases the crumbling effect on ploughed land and ensures active levelling due to the high vibration of the cracker tines. The aggressiveness of the clod board can be adjusted hydraulically from the cab on-the-go. In very wet conditions or if the levelling in front is not needed, the clod board bar can be easily lifted out of work.

There is a full range of levelling equipment and rear rollers available:

Actipress Twin ø 560mm - 220kg/m without soil

- U-profile for high carrying /rolling capacity in light soils

- Clod breaking also in heavy conditions

- Possibility to make different soil profiles by locking the rocking (even or corrogated)

- Self-cleaning effect thanks to the twin u-ring concept

- High stability thanks to the oscillating frame

- High and homogenous consolidation

- Can also work in stony conditions

- Weight when full of soil: 250kg/m

Actipress Single ø560mm - 150kg/m without soil

- Single rotor with U-profile for high carrying /rolling capacity on light soils

- Also for stony conditions due to wide pitch

- 3 models available for a more uniform or rough surface:

with blades/with carbide blades / without blades - More compact design and reduced weight especially suitable for three-point mounted implements.

- Clod breaking also in heavy conditions

- Weight/m when full of soil : 188 kg/m

Cage roller ø 550mm - 90kg/m

- 10 bars for a good loading capacity and operation in wet conditions

- Effective crumbling action

Double cage roller ø 400mm (tube/flat) - 160 kg/m

- Good crumbling

- Precise depth control

Actipack ø 560mm - 205kg/m

- The Kverneland Actipack roller displays its superb working qualities especially on medium to heavy soils and also in wet, stony and sticky conditions thanks to the independent skids and knives.

- The cutting discs break the larger clods whilst the adjustable knives cut the remaining clods resulting in optimal clod breakdown and fine seedbed preparation.

Actiring ø 540mm - 160kg/m

- The Actiring roller is a lighter variant of the Actipack, using the same frame structure and knife system.

- The discs have been replaced by a “V” profile ring, this is saving 60kg/m, which is of critical importance for reducing lifting requirements for mounted equipment.

- Actiring is not recommended in stony conditions.

Easy conversion from working to transport position.

The three-part hydraulic folding gives a transport width of 3.00m and ensures smooth running and safe road transport.

The Turbo T models are EU homologated at 40km/h with pneumatic brakes. A national homologation (25km/h) with hydraulic brake is also available for specific countries.

For the efficient establishment of cover crops in one pass with stubbling, the Turbo T i-Tiller can be combined with a front hopper f-drill and one or two distribution head systems above the rear roller. In combination with the f-drill with ELDOS metering device, the seeds are metered, conveyed and distributed into the soil flow via a baffle plate, either before or behind the rear roller. Placing the seed before the rear roller of finger-following harrow ensures optimal seed-to-soil contact.

Technical specifications

Technical specifications

Download brochureModel |

Frame |

No. of tines |

No. of tine rows |

Working width / transport width (m) |

Turbo 6500T i-Tiller |

trailed fold |

33 |

5 |

6.18 / 3.00 |

Turbo 8000T i-Tiller |

trailed fold |

41 |

5 |

7.68 / 3.00 |