PWM for iXtrack

Kverneland iXtrack T4 and T6 trailed sprayers can now be equipped with iXflow-Pulse.

This innovative development brings Pulse Width Modulation (PWM), in combination with the heavy duty HSS 30-40m boom range, to deliver greater accuracy and precision through fine-tuning of droplet size, coverage and water volumes.

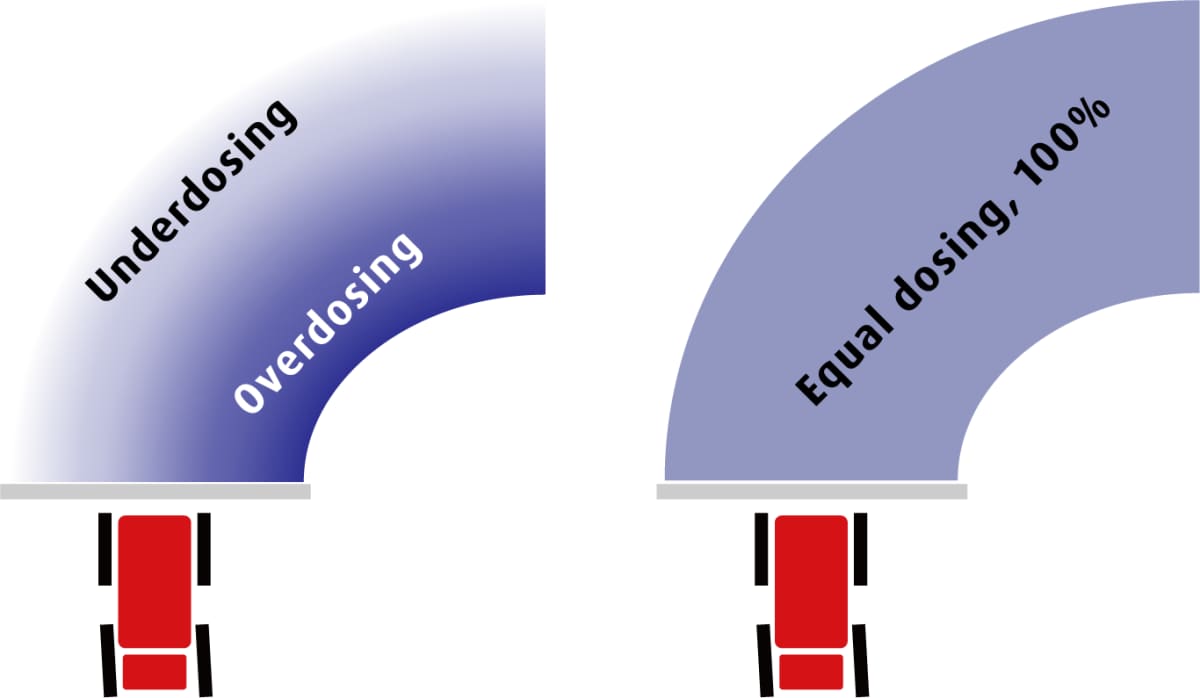

Using Raven’s Hawkeye to underpin the system, Kverneland Group Mechatronics has integrated PWM control into existing iXspray software. As a PWM system, iXflow-Pulse manages the duty cycle for opening and closing times of individual nozzles, to maintain droplet size and pressure, without impacting on the desired application rate.

Advantages include an extension of the working range of a single nozzle system, plus a greater ability to respond to changes in spraying speed. These include curve compensation to manage the boom speed differential from one end of the boom to the other; starting and stopping on headlands; slowing down during turning; and managing forward speed changes when going up or downhill.

TwinFill simplifies multi-tank management

Technology continues to evolve with the introduction of Twin Fill software, to simplify multi-tank management, such as the iXter B with iXtra front tank. Twin Fill ensures that the correct volumes of liquid in the correct concentrations for each tank, and are correctly mixed, split and transferred.

When induction is complete, Twin Fill then ensures both tanks are correctly topped-up to the desired volumes with clean water. It is a process that avoids having to measure out all pesticides twice, and in different amounts, to separately fill a twin-tank set-up.

CTS improves pesticide handling

A Closed Transfer System (CTS) has been developed for integration into the induction hopper of iXtrack trailed sprayers, to avoid the need to manually open containers and pour out the contents.

Once mounted on the CTS unit, products flow in a controlled and measured manner, even with part-can volumes. Using suction and pressure connections, empty containers can be cleaned and rinsed before removal from the CTS unit.

Kverneland’s innovative design enables the remaining induction bowl assembly to provide operational flexibility for those needing to add powders or granules into the tank mix.